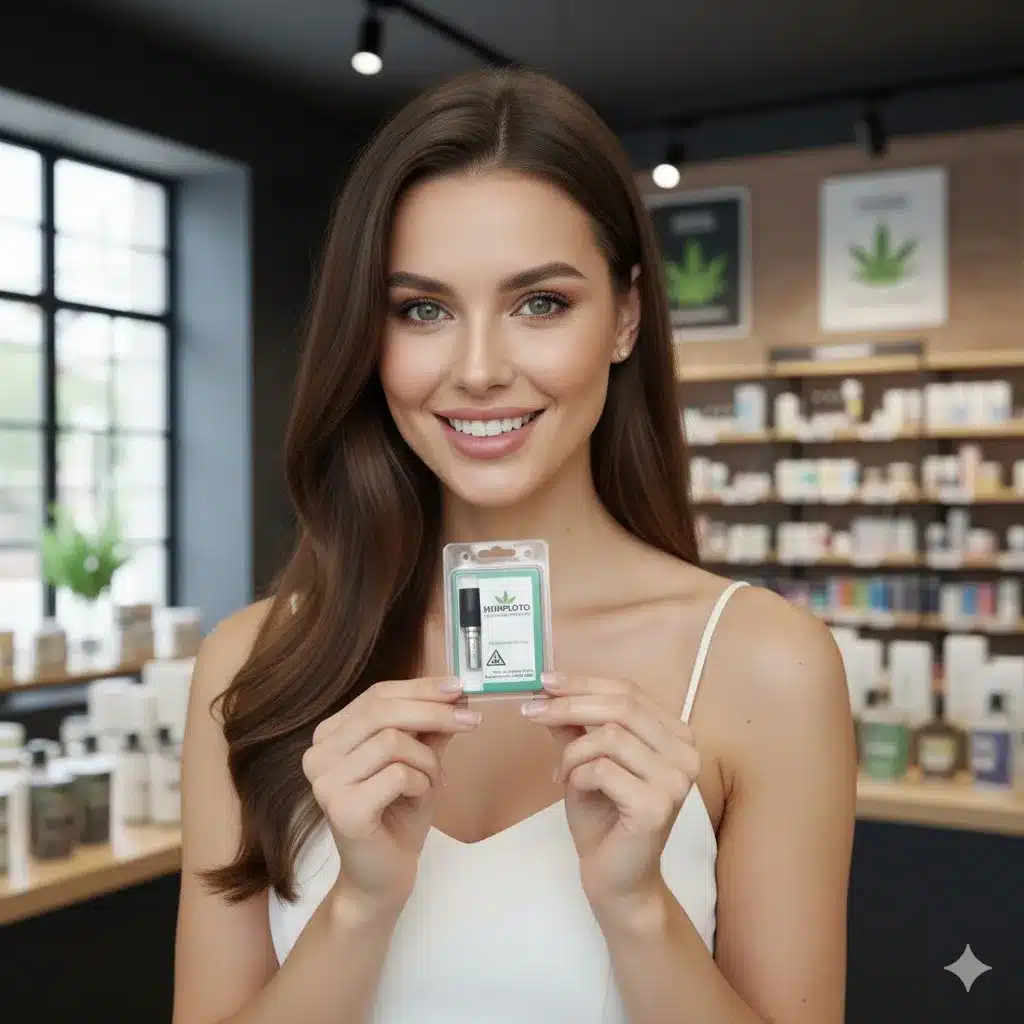

For cannabis brands, packaging is more than protection—it’s a chance to stand out, stay compliant, and build customer trust. But when flexibility meets regulation, not all formats deliver. That’s where clamshell cannabis packaging comes in: a secure, stylish solution.

Clamshell cannabis packaging is a hinged, rigid plastic or biodegradable container designed for pre-rolls, vapes, and edibles. It protects products, supports branding, and complies with child-resistant regulations.

If you’re exploring packaging options that marry compliance and design, clamshells deserve a close look. Let’s break down their features, benefits, and why they’re gaining traction in the cannabis space.

Packaging isn’t just a formality—it’s a reflection of your brand values and product integrity. Clamshell cannabis packaging offers a rare mix of structure, style, and safety. Here’s how it works, and how to make the most of it.

Definition and Structure of Clamshell Packaging

Brands often struggle to balance product protection with visual appeal. Flimsy pouches can feel disposable, while overly complex boxes add cost. Clamshell packaging solves both problems with a clean, protective design.

Clamshell packaging is a rigid, hinged container molded to hold cannabis products securely. It opens like a shell and often includes inserts for organization or display.

Whether you’re selling vape carts, pre-rolls, or gummies, clamshells offer form-fitting security with a strong visual presence.

How the Structure Works

At its simplest, a clamshell package consists of two rigid halves connected by a hinge. The interior is often custom-molded to cradle the product securely, while the exterior can be sealed with a locking tab, heat seal, or adhesive label. This minimizes movement, damage, and contamination during transport or retail display.

Common Materials Used

Most cannabis clamshells are made from PET (polyethylene terephthalate) or rPET (recycled PET). For eco-conscious brands, biodegradable PLA (polylactic acid) is becoming popular. Each material affects transparency, weight, cost, and sustainability footprint.

Visual and Functional Benefits

Unlike cartons or pouches, clamshells showcase the product. Clear lids or windows allow customers to see the item inside, boosting confidence and shelf appeal. And because they’re rigid, they resist crushing—ideal for fragile or shaped items like glass vape cartridges.

| Material | Característica | Suitability |

|---|---|---|

| PET | Durable and clear | Most cannabis formats |

| rPET | Recycled version of PET | Sustainable packaging goals |

| PLA | Biodegradable and plant-based | Eco-focused brands |

Why Cannabis Brands Choose Clamshell Packaging

Packaging isn’t just a vessel—it’s the first handshake with your customer. For cannabis products, that handshake needs to say: “Safe, premium, and worth the price.” Clamshells do exactly that.

Cannabis brands choose clamshell packaging for its visibility, structure, and compatibility with branding and compliance. It elevates the product while protecting it.

For retail environments especially, clamshells deliver a professional, polished look that outshines cheaper options.

Visual Appeal at Point-of-Sale

Retail is still king in cannabis. Clamshells with clear windows or lids allow dispensary customers to see the product—key in states where touching is off-limits. Studies show that transparent packaging can increase product trust and purchase likelihood by up to 30%.

Protective Performance

Clamshells resist impact and maintain shape during shipping and storage. Pre-rolls arrive intact. Vape carts don’t rattle or break. For high-value products, this protection translates into fewer returns and better user experience.

Easy to Brand

The flat exterior of a clamshell is prime real estate. Full-color printing, stickers, embossing, and inserts all work well. For example, Jason Miller, a client running a dispensary in Canada, upgraded his vape line with custom clamshells featuring branded trays and labels. Within three months, his repurchase rate jumped by 18%.

| Advantage | Beneficio |

|---|---|

| Rigid protection | Prevents damage in transit |

| Visibility | Showcases product directly |

| Branding space | Supports logo, messaging, legal labels |

Compliance and Child-Resistance Options

Compliance can’t be an afterthought. One packaging misstep and a product batch could be banned from retail. Clamshells offer built-in options to stay ahead of regulation.

Clamshell cannabis packaging can include certified child-resistant mechanisms that meet ASTM and PPPA requirements in the U.S. and Health Canada’s safety standards.

This makes them a reliable option for brands distributing in regulated markets where safety is mandatory.

Understanding CR Certification

Child-resistant (CR) packaging needs to pass a series of lab tests—typically with children under 5 years old and adults over 50. These tests verify that kids can’t easily open the package, while seniors still can. Clamshells with squeeze-release tabs or dual-locks are common solutions.

Built-in Safety Features

Rather than adding separate child-resistant closures, many clamshell designs build CR features directly into the mold. That means fewer parts to assemble, no extra cost for CR caps, and a sleeker product.

Legal Labels and Tamper Evident Elements

Most markets require tamper-evident features—clamshells support these easily via heat seals, perforated tabs, or security stickers. Plus, their flat surface allows compliant labeling in multiple languages and formats.

| Requirement | Clamshell Solution |

|---|---|

| Child-resistance | Integrated locks |

| Tamper evidence | Heat seals or perforations |

| Label space | Wide surface area for compliance data |

Clamshell vs. Other Cannabis Packaging Types

Choosing packaging is never just about looks—it’s about what works best for your product, your brand, and your supply chain. So how do clamshells compare?

Clamshells offer better protection and product visibility than flexible pouches or folding cartons. They’re also lighter and more affordable than metal tins.

That makes them an ideal middle ground for many cannabis SKUs.

Compared to Pouches

Pouches are cheap and flexible but offer little structure. They can tear, wrinkle, or feel low-end—especially for premium products. Clamshells, in contrast, keep their shape and signal quality on-shelf.

Compared to Tins

Tins are durable and often child-resistant, but they’re heavy and expensive to ship. Clamshells offer similar protection but at a lower cost and weight. Plus, they can be transparent—something tins can’t offer.

Compared to Folding Cartons

Boxes provide good branding space but need inserts to protect the product inside. Clamshells eliminate that extra component—they’re both container and support in one.

| Tipo de envase | Strengths | Weaknesses |

|---|---|---|

| Pouches | Low cost, flexible | Low protection, hard to brand |

| Tins | Strong, premium | Heavy, costly |

| Boxes | Customizable, stackable | Need inserts |

| Clamshells | Secure, visible, versatile | Mid-range cost |

Customization and Branding Possibilities

Packaging is one of the few touchpoints customers physically engage with. When done well, it leaves a lasting impression—and keeps them coming back.

Clamshell packaging is highly customizable, supporting various shapes, colors, finishes, inserts, and printing options to reflect a brand’s identity.

This turns basic packaging into a storytelling platform.

Surface Treatments

You can add embossed logos, matte finishes, metallic inks, or even soft-touch coatings. These upgrades add tactile and visual value. For luxury SKUs, these finishes make a difference in how a customer perceives the product before they ever open it.

Insert Design

Internal trays, cards, or molded supports can hold multiple items and reinforce branding. For example, a pre-roll brand might include a cardboard insert with strain details or lifestyle messaging.

Shape and Color Control

Custom tooling allows you to design non-standard shapes—like hexagons or layered chambers. Color matching to your brand palette keeps the experience cohesive from ad to unboxing.

| Custom Feature | Use Case | Brand Impact |

|---|---|---|

| Embossed lid | Logo prominence | Premium feel |

| Molded tray | Product security | Upscale display |

| Colored base | SKU differentiation | Retail clarity |

Choosing the Right Clamshell Supplier

A great design is only as good as its execution. If your supplier misses the mark on quality or compliance, your product suffers—even before it hits the shelf.

Choose a clamshell packaging supplier that offers in-house manufacturing, compliance testing, visual proofing, and responsive communication.

This ensures consistency, legal readiness, and faster time-to-market.

What to Look For

Reliable suppliers have full production capabilities—rolling, slitting, molding, polishing—and test their packaging for compliance. Ask for child-resistance certification (ASTM D3475 or PPPA), tamper evidence options, and mold customization samples.

Proof and Prototyping

Good partners offer CAD drawings, sample molds, and 3D renderings before full production. This avoids expensive rework and helps you catch design flaws early.

Communication and Lead Time

Short timelines and changing regulations mean you need quick responses. Jason, our client in the U.S., saved over two weeks on his last launch by working with a factory that provided digital proofs within 48 hours and maintained consistent weekly updates.

| Supplier Feature | Por qué es importante |

|---|---|

| In-house production | Better quality control |

| CR certification | Legal market access |

| Sample proofing | Avoid costly mistakes |

| Digital communication | Faster decision-making |

Conclusión

Clamshell cannabis packaging combines visual appeal, rigid protection, and regulatory compliance into one versatile format. It’s a packaging choice that works hard—on shelf, in transit, and in the hands of your customers.