To make custom mylar bags, start by selecting food-safe materials and the right thickness (3–5 mil), then choose a multi-layer lamination structure for odor and moisture protection.

Design a compliant layout with THC icons and print files, select your printing method (digital, flexo, or gravure), apply finishes like matte or holographic, and finalize bag shape, closures (like child-resistant zippers), and tear notches. After quality inspection, bags are packed and shipped by air or sea with lead times ranging from 15–35 days.

Step 1: Choose the Right Material and Thickness

You can’t custom a mylar bag on weak material. The foundation of a good custom mylar bag lies in barrier strength, food safety, and tactile feel.

Start with FDA-grade PET or BOPET material, and choose a thickness (3–5 mil) based on your product type—pre-rolls, gummies, or flower.

This ensures odor control, light protection, and durability during transport.

What "Mylar" Really Means

“Mylar” refers to BOPET film—strong, clear, and moisture-resistant. For cannabis use, it’s often laminated with PE for sealability or foil for light protection. Materials should be food-safe and compliant with your target market’s standards.

Thickness Guidelines

- 3 mil (75 microns): Light products or samples

- 4 mil (100 microns): Versatile for pre-rolls or 3.5g flower

- 5 mil (125 microns): Heavy-duty for gummies or 7g flower bags

Bonus: Smell-Proof Options

Looking for custom smell proof mylar bags? Ask for laminated foil structures like PET/AL/PE, which block odor better than clear options.

| Thickness | Best For | Duurzaamheid |

|---|---|---|

| 3 mil | Small edibles | Moderate |

| 4 mil | Pre-rolls / 3.5g flower | Strong |

| 5 mil | 7g+ flower / gummies | Very strong |

Step 2: Select the Lamination Structure

The lamination structure turns plastic into protection. It affects everything—barrier performance, shelf life, and printing results.

Most custom mylar bags use 2–3 layers: PET or BOPP for print, aluminum or VMPET for barrier, and PE or CPP for sealing.

Your lamination choices depend on product type, storage needs, and finish.

Common Cannabis Lamination Types

- PET/VMPET/PE: Most common, affordable, odor-proof

- PET/AL/PE: Premium, heavy barrier and foil appearance

- BOPP/CPP: Budget-friendly, low barrier

For DIY Creators

If you’re exploring mylar bag printing DIY, look for laminates that support digital ink adhesion without curling or bubbling.

Add-on Effects

Matte, holographic, or soft-touch surfaces are usually baked into lamination—not added later. For example, custom holographic mylar bags require special base films.

| Structure | Barrier Strength | Use Case |

|---|---|---|

| PET/VMPET/PE | Hoog | Flower / Edibles |

| PET/AL/PE | Zeer hoog | Concentrates |

| BOPP/CPP | Medium | Promotional samples |

Step 3: Design Your Layout and Print File

A well-designed printed mylar bag isn’t just beautiful—it’s compliant and production-ready.

Prepare a 300dpi CMYK print file in vector format, using your supplier’s dieline and leaving room for warnings, batch codes, and THC icons.

Good design helps your product stand out and stay legal.

File Requirements

- File format: AI or PDF

- Resolution: 300dpi

- Color Mode: CMYK or Pantone

- Fonts: Outlined

- Safe zones: 3–5mm from trim edge

Design Tips

- Include QR code space if required

- Use scalable icons and flat backgrounds for clean print

- Avoid gradients unless printing method supports them

For Wholesale Orders

If you’re preparing custom mylar bags wholesale, set up each SKU as a separate artboard with clear naming (e.g., “Indica 3.5g_front.ai”).

| Design Element | Requirement |

|---|---|

| THC Icon | Mandatory in most U.S. states |

| Net Weight | 1g / 3.5g / 7g / custom |

| Warning Copy | Often bilingual (e.g., Canada) |

Step 4: Printing and Surface Finishing

This is where your bag transforms from a blank canvas into a retail product. The printing method affects cost, color fidelity, and MOQ.

Choose between gravure, flexo, or digital printing based on your quantity and desired detail. Then add finishes like matte, gloss, or soft-touch.

Printed mylar bags are only as good as their surface quality.

Printing Methods

- Digital: Great for 500–1,000 bags, fast prototyping

- Flexo: Efficient for mid-runs (3K–10K), low plate cost

- Gravure: High quality, best for 10K+ runs

Surface Finishes

- Matte: Soft, low-shine

- Gloss: Vivid color, reflective

- Soft-touch: Luxury feel, fingerprint-prone

- Spot UV: Adds dimension to logos

Finishing for Premium Products

Want a luxury look? Combine matte lamination with spot UV on your logo, or go full foil for eye-catching shine.

| Finish | Look | Feel |

|---|---|---|

| Matte | Subtle | Smooth |

| Gloss | Bold | Slick |

| Soft-touch | Premium | Velvety |

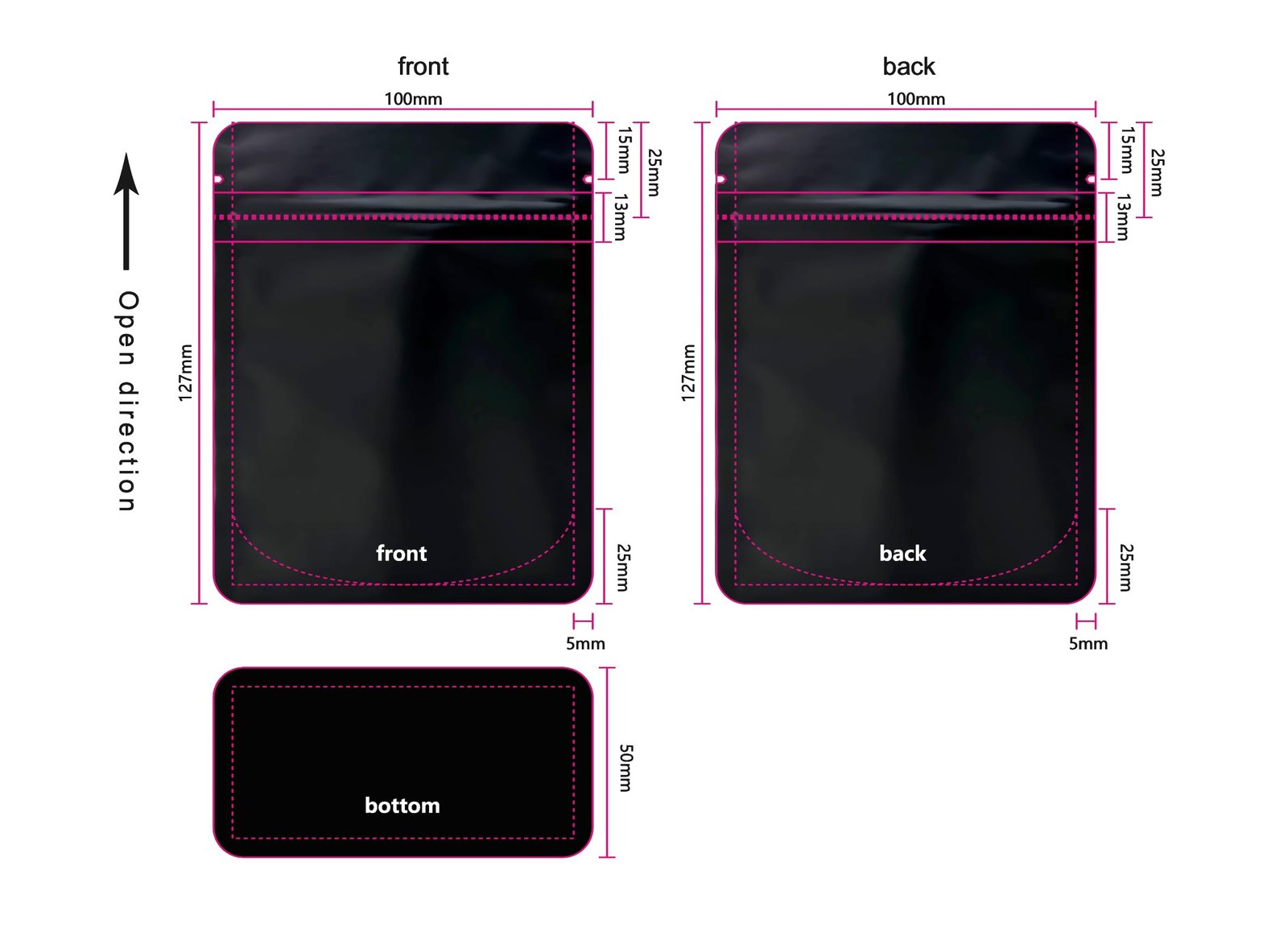

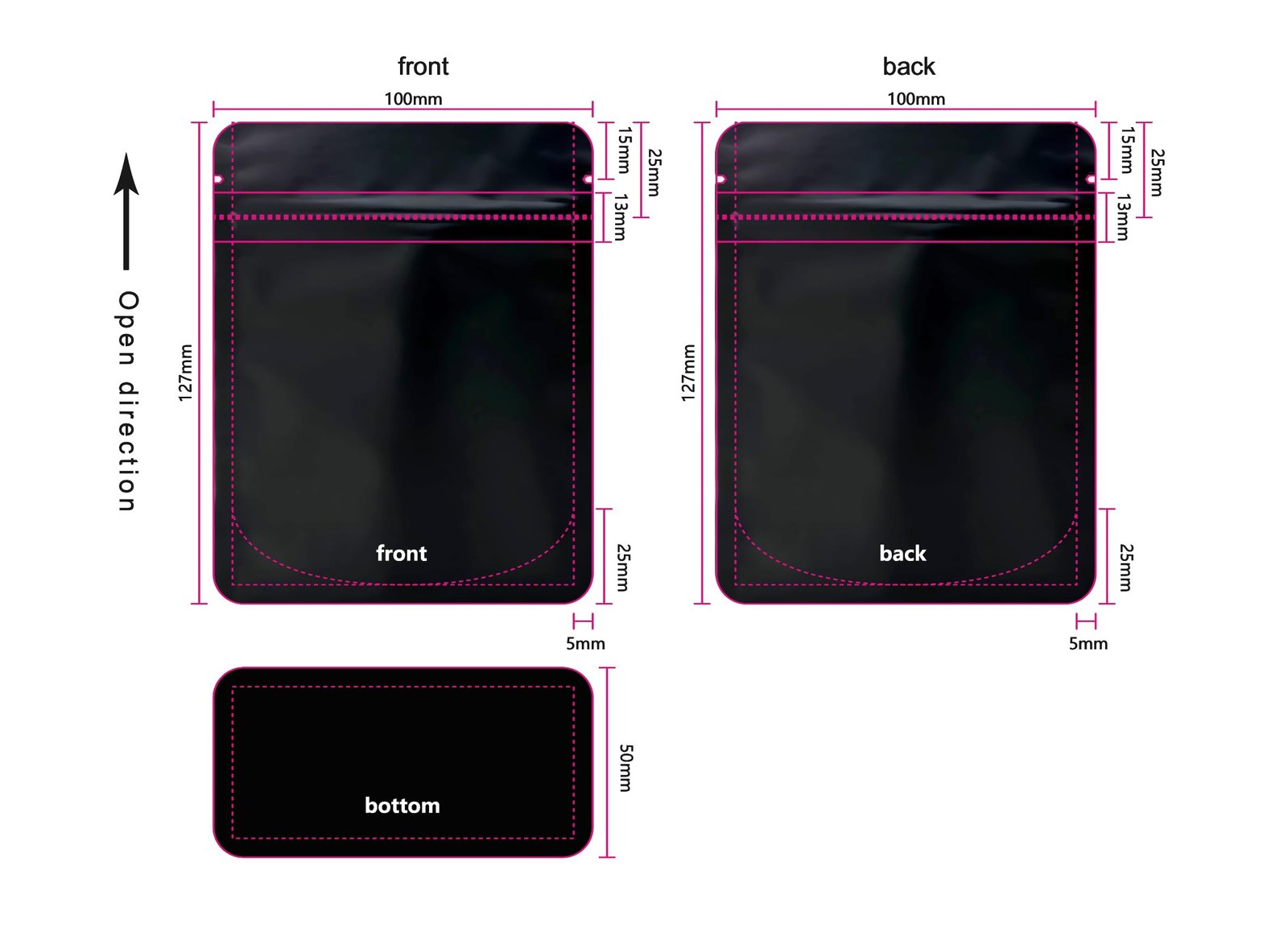

Step 5: Cutting, Sealing, and Adding Closures

Now your printed roll stock is converted into finished bags. This stage defines form, function, and user experience.

Select a bag type (stand-up, gusseted, flat) and closure (zipper, CR zipper, tear notch) based on your product’s use and regulations.

This is also where child-resistant (CR) features get added.

Bag Types

- 3-side seal: Flat, simple, cost-efficient

- Stand-up pouch: Holds flower well, shelf-stable

- Gusseted bag: Extra volume, stable base

- CR bags: Compliant for THC products

Closures and Features

- Standard zipper: Resealable, easy

- Child-resistant zipper: Required in many states

- Tear notch: Adds ease-of-use

- Hang hole: Retail peg display

Tip: For small brands needing flexibility, look for manufacturers who offer custom mylar bags with low MOQ on complex CR features.

| Functie | Functie | Notes |

|---|---|---|

| CR Zip | Legal requirement | Ask for test reports |

| Hang Hole | Retail ready | Optional |

| Tear Notch | Better UX | No extra cost |

Step 6: Quality Inspection and Packaging

Cut corners here, and all your design work goes to waste. Proper QC ensures you receive bags that are usable and on spec.

Check seal strength, CR function, print quality, and odor retention. Then ensure bags are packed by SKU and protected during transit.

You’re not just buying bags—you’re protecting your product and reputation.

Inspection Checklist

- Are all zippers aligned?

- Are colors accurate and vibrant?

- Are seals strong but openable?

- Are there scratches, misprints, or odor leakage?

Packaging for Shipping

Bags are poly-wrapped, boxed, and palletized. Labels should match your PO for smooth warehouse intake.

Ask for Visual Proofs

Before full shipment, request photos or live video of packed goods. For large orders, consider a third-party inspection.

| QC Factor | Waarom het belangrijk is |

|---|---|

| Print Alignment | Keeps branding sharp |

| Seal Strength | Prevents air/moisture entry |

| CR Zip Function | Legal and consumer safety |

Step 7: Shipping and Lead Time Considerations

Production’s done—now it’s time to get your bags where they need to go. How fast and how much depends on your shipping method.

Plan for 15–35 days depending on whether you choose air, sea, or express freight. Include customs docs and CR certificates to avoid delays.

Late packaging = delayed launch. Don’t wing this step.

Lead Time Estimates

- Production: 12–18 working days

- Inspection + Packing: 2–3 days

- Shipping:

- Sea: 20–30 days

- Air: 7–12 days

- Express (DHL/UPS): 3–6 days

Documents You’ll Need

- Commercial Invoice

- Packing List

- HS Code (e.g., 3923.21)

- CR Certificate (if required)

- Country of Origin declaration

Wholesale Orders

If you’re sourcing custom mylar bags wholesale, always get an ETA confirmed in writing—and pad 7 days for port or customs delays.

| Mode | Speed | Kosten |

|---|---|---|

| Express | Fastest | Highest |

| Air Freight | Mid-range | Mid-level |

| Sea Freight | Slowest | Lowest |

Conclusie

Making custom mylar bags is a repeatable, scalable process—if you plan it right. From choosing materials to print prep and compliance, each step affects how your packaging supports your brand. The good news? Once you’ve done it once, you can repeat it better, faster, and smarter.