Trump’s trade war with China has caused big problems.

The cost of cannabis packaging now costs more because of new tariffs. These tariffs include a 245% tax on Chinese goods. Businesses must deal with challenges like paying upfront to lock prices.

This adds financial pressure to their operations. For instance, vape products from China now have a 150% tariff. This makes them much more expensive. These changes hurt the cannabis market and its stability.

As far as I’m concerned, as someone who’s been in marijuana packaging production for 10 years, the cost of manufacturing in the U.S. is still higher than in China, on top of that tariff.

What Are Trump’s Proposed Tariff Changes for Chinese Imports in 2025?

Overview of the 2025 tariff rates and affected product categories

Trump’s trade war caused higher taxes on goods from China. By 2025, U.S. tariffs on China hit record levels, up to 245%. These taxes affect many items, including cannabis packaging supplies. Here’s a simple table showing the tariff rates:

Country | Tariff Rate |

|---|---|

All Countries | 10% |

57 Specific Countries | 11% to 50% |

Non-compliant Goods | 25% |

China | 245% |

Canada | 25% |

UK | 10% |

European Union | Up to 25% |

Most goods are subject to a 10% tariff, but China faces the highest tariffs. Although most cannabis companies can pass on this tariff cost to consumers by raising prices, consumers will still prefer to buy from the cheapest source.

Specific impacts of U.S. tariffs on China for cannabis packaging materials

O cannabis industry depends on China for packaging like jars and tins. U.S. tariffs have made these items much pricier. For example:

Plastic jars and lids now cost a lot more due to the 245% tariff.

Glass containers, used for cannabis flower, are less affordable now.

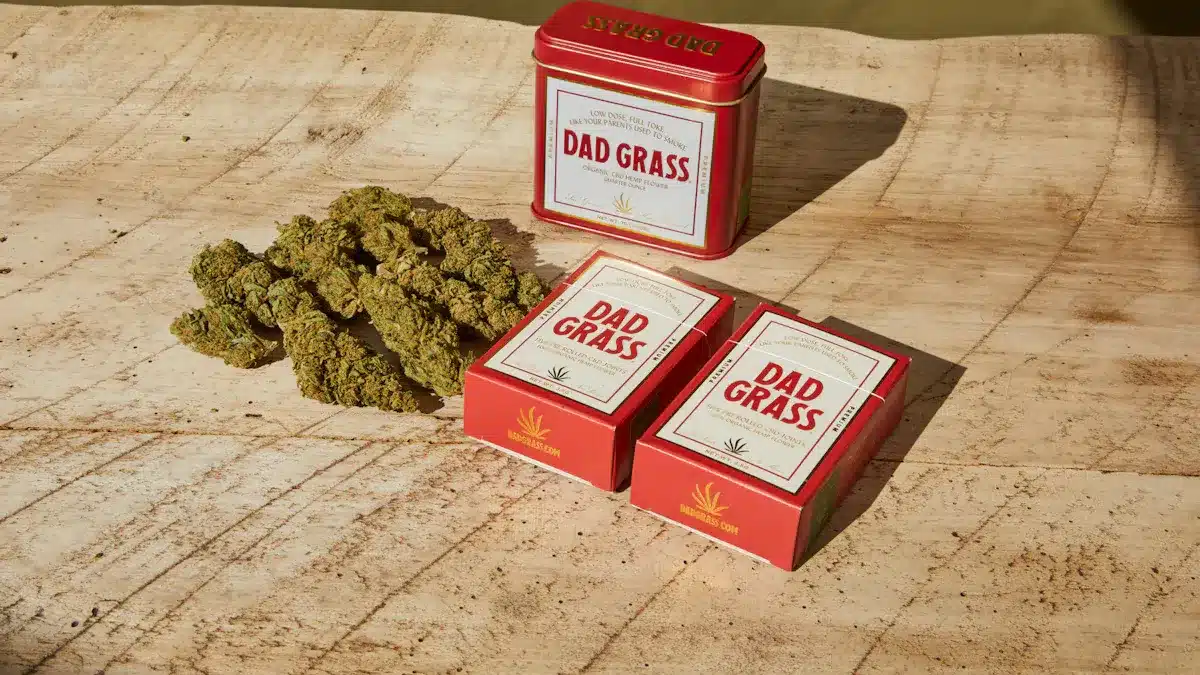

Metal tins and closures also face extra taxes, like a 25% steel and aluminum tariff.

These higher costs push companies to look for new suppliers. Still, many rely on China because it’s cheaper and produces more.

Packaging Material | Likely HTS Chapter(s) | Example HTS Subheadings | Base MFN Duty Rate Range (General Column 1) | Likely Subject to Additional China Tariffs (2025 Scenario)? |

|---|---|---|---|---|

Plastic Jars/Bottles/Tubes | 39 |

| 0% – 6.5% | Yes |

Plastic Bags/Pouches | 39 |

| 0% – 5.3% | Yes |

Plastic Lids/Closures | 39 |

| 5.3% – 6.5% | Yes |

Glass Jars/Bottles | 70 |

| Often Free | Yes |

Metal Tins – Steel | 73 |

| Often Free – 4.9% | Yes (+ potential 25% steel tariff) |

Metal Tins/Tubes – Aluminum | 76 |

| Often Free – 5.7% | Yes (+ mandatory 25% aluminum tariff ) |

Metal Lids/Closures | 83 |

| Often 2.6% – 5.7% | Yes |

Paper/Cardboard Boxes/Cartons | 48 |

| Often Free | Yes |

Paper/Cardboard Labels | 48 |

| Often Free | Yes |

Timeline and policy volatility affecting cannabis businesses

The timing of these tariff changes has caused confusion. On March 4, 2025, tariffs on Chinese goods went up by 20%. That same day, another 20% IEEPA tariff was added. Here’s a quick summary:

Tariff Type | Applicable Rate | Scope | Key Effective Dates / Timeline (2025) |

|---|---|---|---|

Initial China Tariff (Fentanyl/Border Related) | 10% (additional) | All goods from China | Feb 4 |

Increased China Tariff | 20% (total additional) | All goods from China | Mar 4 |

Baseline Tariff | 10% | Nearly all imports (including China) | Apr 5 |

China-Specific Reciprocal/Retaliatory Tariffs | Escalated: 84% -> 104% -> 125% (additional rates) | Most goods from China (exceptions unclear/disputed) | Apr 9 (84%) , Apr 8 announcement (104%) , Apr 10 (125%) |

Total Minimum China Tariff | 145% (cumulative: 125% + 20%) | Most goods from China | Clarified Apr 10 , Applies to goods subject to 125% rate |

Global Steel Tariff | 25% | All steel imports (incl. China) | Mar 12 |

Global Aluminum Tariff | 25% | All aluminum imports (incl. China) | Mar 12 (general), Apr 2 (cans/canned beer) |

De Minimis Treatment Change | Duty Imposed (rate varies, e.g., 90% ad valorem + fee) | Low-value (<$800) shipments from China | Effective May 2 (duty-free ends), phased-in fee increases |

Electronics Exception (Disputed) | Initially exempt from reciprocal, later 20% suggested | Smartphones, laptops, semiconductors | Apr 11-14 (confusion period) |

These rapid changes have made it difficult for cannabis companies to develop long-term plans. Unpredictable policies have further exacerbated challenges, making it hard for businesses to adjust. Which country should they source from, and can they still get the same quality and prices as before?

Which Cannabis Packaging Materials Could Be Affected by the New Tariffs?

Common materials like plastics, glass, and metals used in cannabis packaging

Embalagem de cannabis uses three main materials: plastics, glass, and metals. Plastics are popular because they are cheap and flexible. They are used for jars, lids, and child-safe containers. Glass is often chosen for high-end products like flower and concentrates. It looks nice and keeps products fresh. Metals, such as aluminum and steel, are used for tins and closures. Aluminum could make $1.5 billion by 2032, while steel might reach $1.2 billion. Tinplate, another metal, is also growing and may earn $0.8 billion by 2032.

How tariffs on these materials will increase the cost of cannabis packaging

New tariffs have made these materials cost a lot more. For plastics, prices may rise by 15-25%, according to the 2025 Tariff Report. This affects jars, lids, and other plastic parts. Glass containers now have a 145% tariff, making them expensive. Metals like aluminum and steel are hit even harder. Aluminum tins face both a 145% tariff and a 25% global aluminum tax. These increases make it tough for businesses to keep prices low.

Examples of price changes for key packaging items

The price jumps are shocking. A plastic jar that was $0.50 now costs $1.23. Vape cartridge hardware went from $1.00 to $2.45. A small aluminum tin, once $0.40, now costs $1.10 due to tariffs. These higher prices force companies to change how they buy and price their products.

How Will Increased Tariffs Impact Pricing and Supply Chain Planning?

Direct cost increases for cannabis businesses and their profit margins

Trump’s tariffs are making things harder for cannabis companies. These taxes raise the cost of packaging, which is very important. For example, vape products that used to cost $3-$4 now cost $10 more. This big price jump makes it tough for small businesses to make money.

At this time, most people tend to overlook quality when purchasing products and focus solely on price. This mindset could lead to increased costs for many small businesses, as quality packaging plays a crucial role in brand image and product freshness.

Representative Packaging Item | Estimated Base Cost from China (Pre-Tariff) | Est. Cost with 10% Baseline Tariff | Est. Cost with 25% Tariff (e.g., Steel/Alum + Baseline) | Est. Cost with 145% China Tariff (Cumulative) | % Increase vs. Base (145% Tariff) |

|---|---|---|---|---|---|

1g Glass Jar w/ Plastic CR Lid | $0.50 | $0.55 | $0.63 (Approx.) | $1.23 | +145% |

0.5mL Vape Cartridge Hardware | $1.00 | $1.10 | $1.25 (Approx.) | $2.45 | +145% |

Child-Resistant Mylar Pouch (Med) | $0.15 | $0.17 | $0.19 (Approx.) | $0.37 | +145% |

Aluminum Tin (Small) | $0.40 | $0.44 | $0.54 (Base + 25% Alum) | $1.10 (Base + 25% Alum + 145% China) | +175% (Compounded) |

Export to Sheets

Potential price hikes for consumers and competition with the illicit market

Shoppers are already paying more because of these tariffs. Packaging costs have gone up, and businesses are passing this on. This means cannabis products in stores now cost more. For example, metal packaging faces a 30% tariff, raising prices even more.

But raising prices can be risky. Legal cannabis competes with illegal sellers who don’t have these costs. If legal products get too pricey, people might buy from unregulated sources. This hurts legal businesses and public safety.

Challenges in maintaining supply chain efficiency and reliability

Tariffs have messed up supply chains for cannabis businesses. Many are changing how they get supplies to fix this. Some companies now make products closer to home. For instance, Custom Cones USA moved some production to the U.S. to save time and money. Ispire Technology expanded in Malaysia to cut costs and help the environment.

However, these measures require significant investment, particularly given the time required for policy approvals in the United States and worker training in Southeast Asia.

Shipping companies are also adjusting. Talaria is using new technology and more suppliers to handle rising costs. These changes show how important it is to stay flexible. But not all businesses can afford these changes, leaving smaller ones at risk.

The cannabis industry still faces problems from Trump’s policies. Companies must deal with these issues while keeping products affordable and legal. By finding smarter ways to make and get supplies, businesses can build stronger supply chains and rely less on high-tariff areas.

What Can Cannabis Brands Do to Handle Higher Import Costs?

Renegotiating deals with current suppliers

Sometimes, renegotiating with suppliers can help manage costs. Businesses can save money by using data and improving partnerships. For example, pointing out late deliveries can lead to better prices or terms.

Here’s a table showing how companies saved money through negotiations:

Tipo de prova | Descrição | Outcome |

|---|---|---|

Delivery Issues | Late deliveries led to a penalty clause. | |

Price Comparisons | Supplier’s prices were higher than average. | Secured better service terms. |

Demand Forecasts | Predicted higher demand helped negotiate volume discounts. | Saved significant costs. |

Building trust with suppliers also helps. Sharing data and feedback can improve efficiency. For example, one company cut delivery delays by 15% through better communication. This lowered production costs by 10%. Working together benefits both sides.

Are There Smart Sourcing or Production Shifts to Consider Now?

Using eco-friendly and reusable packaging to save money

Switching to eco-friendly packaging can cut costs and help brands. Some companies now use materials like hemp and recycled plastics. These options are better for the planet and attract green-minded buyers.

Reusable packaging is another good idea. Businesses can make containers that customers bring back for refills. This lowers waste and saves money over time. By choosing sustainable packaging, cannabis brands can stay ahead and help the environment.

Using technology to improve supply chain planning

Technology helps solve supply chain problems. Tools like artificial intelligence (AI) make things faster and cheaper. AI can predict demand, manage warehouses, and plan shipping better. It can cut transport costs by 30% and reduce extra stock by 25%. It also makes planning more accurate by 75%.

Other tools like GPS and IoT track shipments in real-time. They quickly find problems and keep things running smoothly. Automation also reduces mistakes and speeds up work. By using these tools, cannabis companies can save money and improve their systems.

Here are three tips to try:

Combine shipments to lower delivery costs.

Use different suppliers to avoid tariff issues.

Change product designs to reduce import taxes.

Partnering with local makers for creative packaging

Working with local factories can lead to smart and cheap packaging ideas. Companies like Laurentide Injection Products and Sana Packaging have done this well. They use materials like recycled glass and hemp to make eco-friendly products. This also cuts shipping costs and helps local businesses.

Here’s a quick look at some cool efforts:

Company | Focus on Innovation | Materiais utilizados |

|---|---|---|

Laurentide Injection Products | Local sourcing, custom designs, sustainability | North American-made raw materials |

Silly Nice | Recycled materials, eco-friendly practices | Recycled ocean plastic, hemp |

Sana Packaging | Partnered with Silly Nice for green solutions | 100% recycled glass, renewable hemp |

Local partnerships also mean faster production and better teamwork. It’s good for both businesses and the planet.

What Are the Long-Term Effects on the Cannabis Industry?

Changes in where cannabis packaging is made

Tariffs are changing how companies get cannabis packaging. Many businesses are using fewer Chinese suppliers. Instead, they are looking at Southeast Asia, India, or making products locally. This helps avoid high tariffs and shipping problems. Companies are now rethinking how they get their materials.

Making packaging in the U.S. is becoming more popular. Factories are growing to meet the demand for cannabis packaging. This helps the local economy and cuts shipping costs. While it costs more at first, it offers better reliability over time.

New ideas for eco-friendly packaging

Tariffs are pushing companies to try new ideas. Many are using recycled plastics or hemp for packaging. These materials are better for the planet and attract eco-friendly buyers.

Reusable packaging is also becoming popular. Companies are making containers that customers can refill. This reduces waste and saves money. Making products locally also helps the environment by cutting transportation pollution. Experts think these changes will lead to better packaging designs and materials.

How companies can stay successful in tough times

Cannabis companies need to adjust to stay competitive. Using different suppliers is important. Investing in technology can also help. Tools like AI can predict demand and manage inventory better.

Working with local factories can create unique packaging designs. U.S. factories can help brands stand out with creative ideas. Companies should also teach customers about the benefits of eco-friendly and local packaging. This builds trust and keeps customers loyal, even with higher costs from tariffs.

Trump’s new tariffs have made things harder for the cannabis industry. Packaging costs have gone up a lot, so businesses must change plans. Some are finding new suppliers, while others are making products in the U.S. to rely less on imports. These changes are tough but could lead to new ideas.

Shoppers might pay more because companies are raising prices. Still, the industry can grow if it finds smart solutions. By using eco-friendly packaging and working with local factories, cannabis businesses can stay strong even with these challenges.

📊 Experts say tariffs work like taxes, raising costs and slowing production. The New York Federal Reserve found past trade wars made prices 0.3% higher. Future tariffs could add another 0.4%.