If you’re a grower or dispensary owner, you already know that cannabis flower packaging isn’t just about looking good on the shelf—it’s the frontline defense for preserving potency, staying compliant, and controlling costs. From child-resistant designs to cutting-edge preservation tech, the right packaging can extend shelf life, reduce waste, and elevate your brand in a crowded market.

In this complete buyer’s guide for 2026, we cut through the noise with everything you need to make smart, confident decisions—from state-by-state compliance to material choices and supplier insights. Whether you’re scaling up or launching a boutique batch, buckle up—it’s time to package your cannabis flower like a pro.

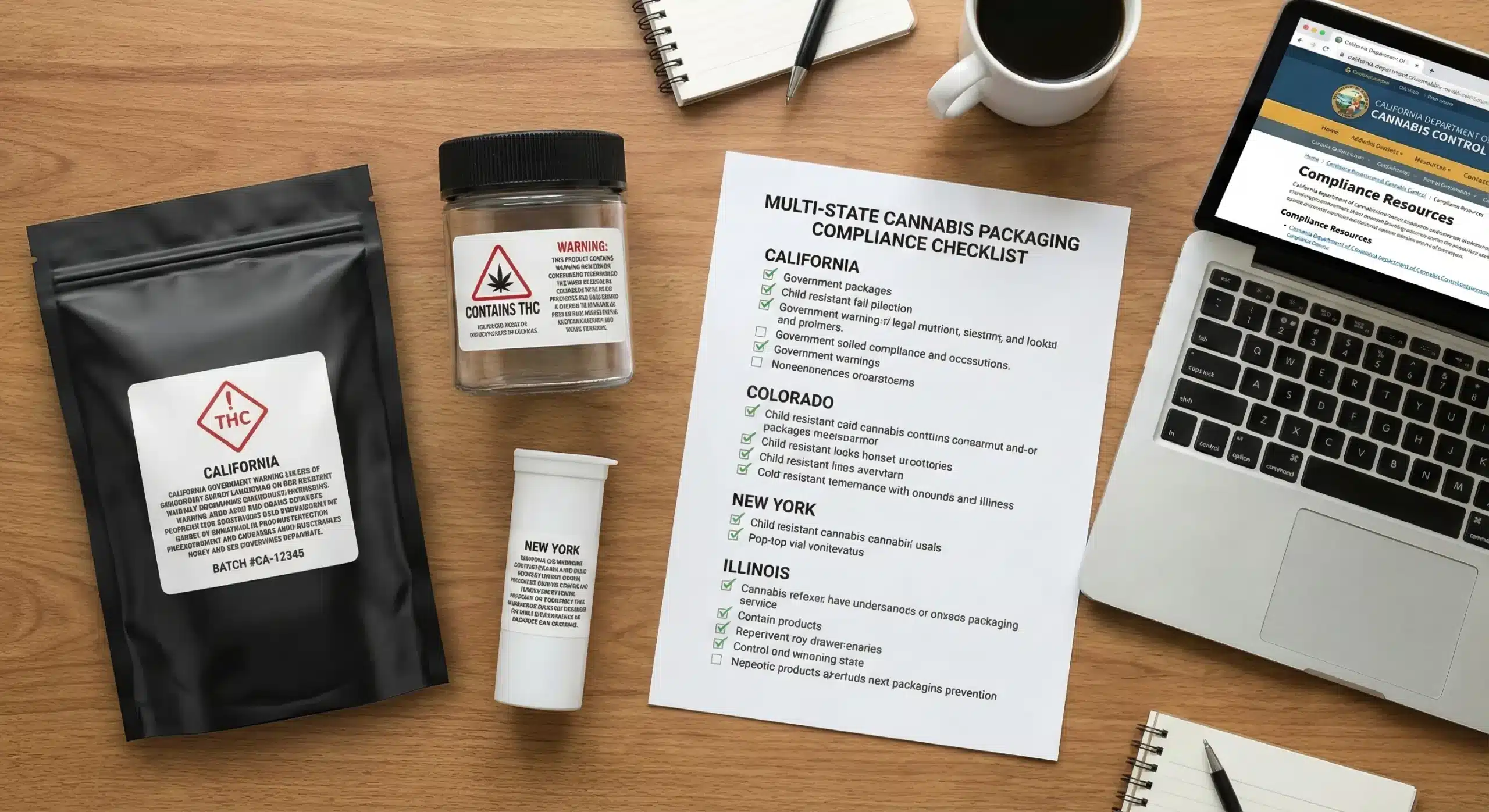

Legal & Compliance Requirements Every Grower Must Know

Navigating cannabis packaging laws can feel like a maze, but knowing the essentials is key to staying compliant and avoiding costly fines. Here’s what you really need to know for 2026:

Federal vs. State-by-State Rules (2026 Overview)

There’s no single federal cannabis packaging law since it’s still federally illegal. The real game-changer is state regulations, which vary—sometimes wildly. Always follow the strictest state rules where you operate.

| State | Child-Resistant Required | Opaque or Light Blocking | Tamper-Evident | Labeling Mandate Highlights |

|---|---|---|---|---|

| California | Yes (CPSC, ASTM) | Opaque required | Yes | Potency, QR codes, warning labels |

| Colorado | Yes (ASTM D3475) | Light-blocking preferred | Yes | Batch info, harvest date |

| New York | Yes | Opaque required | Yes | Allergen info, universal symbols |

| Illinois | Yes | Opaque mandate | Yes | Child safety, recycling info |

| Michigan | Yes | Light-blocking preferred | Yes | Real-time lab data on QR |

| Oklahoma | Yes | Opaque recommended | Yes | Standardized warnings, barcode |

Child-Resistant Certification: What You Must Use

Your packaging has to pass official child-resistant tests. Look for compliance with:

- CPSC (Consumer Product Safety Commission)

- ASTM standards (especially ASTM F963 and D3475 for zippers)

- ISO certifications for international shipments

Beware of packaging that just looks child-resistant but isn’t officially tested. Labs can provide real test certificates, so ask for proof before buying.

Opaque vs. Light-Blocking Packaging

Protecting your flower from UV light is critical to preserving cannabinoids and terpenes. Many states now require either:

- Fully opaque packages (common in CA, NY, IL)

- Or UV-blocking or light-blocking materials (like Miron violet glass or high-barrier films)

This isn’t just about compliance—it’s about keeping quality intact.

Exit Packaging, Tamper-Evidence & Labeling

Your package on the shelf isn’t done once sold. Exit packaging (like exit bags and overwraps) must:

- Be child-resistant

- Have tamper-evident features (seals, tapes, shrink bands)

- Include clear, accurate labeling with:

- Potency levels

- Lot numbers

- Health warnings

- QR codes linking to lab results

Upcoming Changes to Watch (2026)

- California: Tougher recycling claims and stricter opaque rules

- Colorado: New ASTM standards for zippers and caps

- New York: Required QR-linked seed-to-sale tracking

- Illinois: Expanded language and allergen disclosures on labels

- Michigan: Focus on real-time freshness indicators on packaging

- Oklahoma: Moving toward mandatory child-resistant exit bags

Bottom line: Stay ahead by regularly checking state regulations and verifying packaging certifications. It’s not just regulation, it’s your product’s protection—and your business’s future.

Core Goals of Great Cannabis Flower Packaging

When it comes to cannabis flower packaging, the main goal is protection. You want to preserve those valuable terpenes, cannabinoids, and moisture levels because that’s what keeps the flower fresh and potent. Packaging that lets air, light, or moisture in will degrade your product faster — no grower or dispensary wants that.

At the same time, packaging must be child-resistant but also easy enough for seniors and adult consumers to open. Striking that balance isn’t just a legal must; it builds trust with your customers.

Sustainability is another big factor. More buyers today expect eco-friendly packaging—think recyclable materials or biodegradable options. This not only helps the planet but can also boost your brand image.

Finally, with so many brands packed on dispensary shelves, your packaging has to stand out. Custom designs, unique shapes, and clear brand messaging help customers spot your product quickly and build loyalty. Great cannabis flower packaging protects your flower, stays legal, meets modern eco-standards, and helps your brand shine.

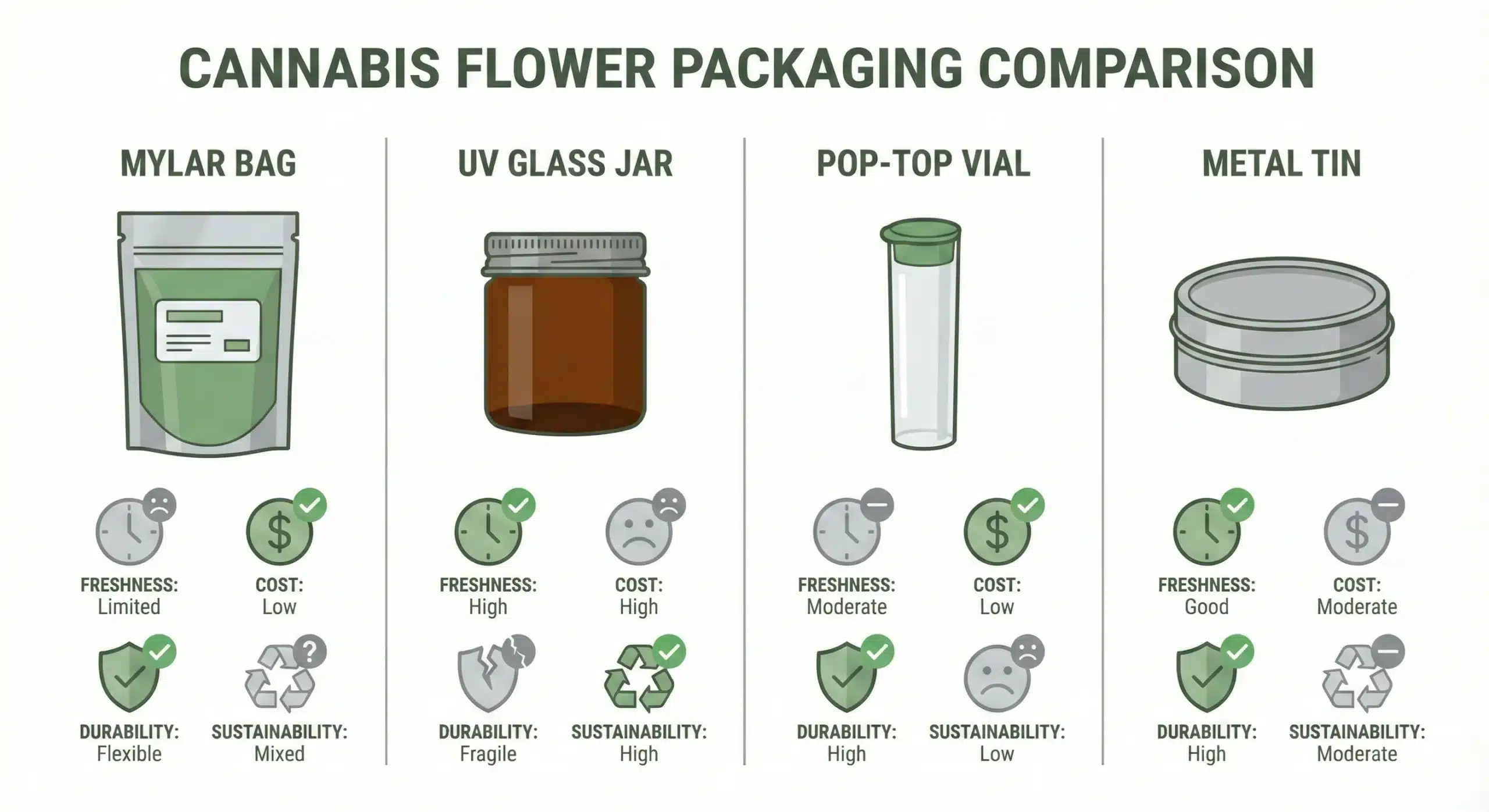

Top Packaging Formats for Dried Flower (Pros, Cons & Best Use-Cases)

When it comes to cannabis flower packaging, choosing the right format is key. Here’s a quick rundown of popular options — with their pros, cons, and when they work best.

Mylar Bags

- Pros: Lightweight, flexible, affordable, and available in stand-up pouches or lay-flat styles. They come in matte or gloss finishes and can be custom printed for branding.

- Cons: Not as durable as glass or rigid containers. Some cheaper Mylar bags may lack true barrier properties.

- Best Use: Great for small to mid-size batches and flower that needs light and moisture protection with a budget-friendly touch.

Glass Jars

- Pros: Preserve terpenes and cannabinoids well, especially UV-blocking or Miron violet glass types. Wide-mouth designs make access easy. Glass is premium and reusable.

- Cons: Heavier, brittle, and typically more expensive upfront. Must include child-resistant lids to comply with regulations.

- Best Use: Ideal for dispensaries or brands that want a high-end look and maximum flower freshness.

Pop-Top Plastic Vials/Drams

- Pros: Lightweight, child-resistant by design, and convenient for single or small-use doses. Easy to stack and transport.

- Cons: Lower barrier to moisture and light compared to glass or Mylar. Not as sustainable.

- Best Use: Perfect for micro-dosing or small quantities sold in dispensaries.

Tin Cans & Metal Containers

- Pros: Durable, opaque, and offer a good barrier to light. Can come with tight seals and custom printing options.

- Cons: Can be bulky and less common, which might confuse customers used to glass and Mylar.

- Best Use: Good for premium or specialty products where durability and look matter.

Rigid Plastic Containers & Hinged Boxes

- Pros: Easy to open, many are child-resistant, and offer solid protection. Often recyclable and lighter than glass.

- Cons: Can look less premium, and not all plastics offer high UV or moisture protection.

- Best Use: Great for mid-level pricing tiers, mixing convenience with protection.

Vacuum-Sealed Options & Nitrogen Flushing

- Pros: Extend shelf life by removing oxygen, preserving terpene profiles and cannabinoids. Often paired with Mylar or plastic pouches.

- Cons: Requires special equipment and can increase packaging costs. Not always reusable.

- Best Use: Best for growers and brands aiming to maximize freshness and shelf stability during transport and storage.

By matching your packaging format to your product needs and customer expectations, you can protect your flower effectively and stand out in a tough market.

Materials Deep Dive: Which One Actually Protects Your Flower?

Choosing the right material is key to keeping your cannabis flower fresh and potent. Not all packaging does the job equally. Here’s a quick look at popular options and what they bring to the table.

Standard Mylar vs. High-Barrier Films

- Standard Mylar: Affordable, moisture-resistant, and light-blocking but has limits against oxygen and odor.

- High-barrier films (7-layer, foil, EVOH): These are advanced options that add extra layers to block oxygen, moisture, and smells better. Perfect if you want longer shelf life and terpene preservation.

UV-Resistant Glass vs. Miron Violet Glass

- UV-resistant glass jars block harmful ultraviolet rays that can degrade cannabinoids and terpenes. Clear glass looks great but offers less protection.

- Miron violet glass is a dark purple glass that naturally filters light, preserving freshness better while still letting customers see the product. A favorite for premium brands looking to stand out.

Food-Grade Plastics (PET, HDPE)

- Both PET and HDPE plastics are FDA-approved for food contact, making them safe for cannabis. They’re lightweight and shatterproof. Look for those with built-in UV blockers and tight seals to protect your flower from air and light damage.

Sustainable Options: Biodegradable Films, PCR Plastics, Hemp-Based Materials

- Sustainability is a growing demand. Biodegradable films break down naturally, reducing landfill waste.

- PCR (Post-Consumer Recycled) plastics reuse existing materials, lowering carbon footprint without sacrificing quality.

- Hemp-based packaging is emerging as a natural, renewable alternative, blending eco-friendliness with solid barrier protection.

Choosing the right material depends on your priorities—whether it’s shelf life, branding, or sustainability. In the U.S. market, brands are balancing protection with consumer demand for eco-conscious packaging more than ever.

Child-Resistant Mechanisms Explained

When it comes to child-resistant cannabis flower packaging, the goal is clear: keep kids out without frustrating adult users. Here’s a quick rundown of the most common mechanisms you’ll see:

- Push-and-Turn Caps: Probably the most familiar—users push down while turning the cap to open. These caps are standard on many cannabis glass jars with CR lids and pop-top plastic vials. They balance safety and ease for seniors.

- Squeeze-Top Pop Tops: These require you to squeeze the sides before popping the lid open. They’re common on pop top vials bulk orders and are easy to use once you know the trick but hard for kids.

- Certified Zippers (ASTM D3475): For mylar bags and flexible packaging, certified zippers pass strict tests (ASTM D3475) to ensure they resist child tampering while staying user-friendly. Don’t just buy any zipper labeled “child-resistant”—look for this certification.

- Pinch-and-Slide or Button-Release: Less common but effective. You pinch or press a button while sliding or lifting the closure. These options are often seen on newer packaging styles aiming for a modern twist on CR mechanisms.

How to Verify Real Child-Resistant Certification

Not all packaging that looks child-resistant actually meets legal standards. When sourcing, check if the packaging is tested in labs accredited for child-resistance, like CPSC-approved facilities. Ask your supplier for:

- Certification documents showing compliance with ASTM or ISO standards

- Testing lab reports verifying mechanisms work as claimed

- Labels or packaging marks proving official CR certification (not just “looks CR”)

Doing this protects your business and keeps your packaging fully compliant with federal and state laws. Remember, reliable child-resistant cannabis packaging isn’t just a nice-to-have—it’s a must for legal operations in 2026 and beyond.

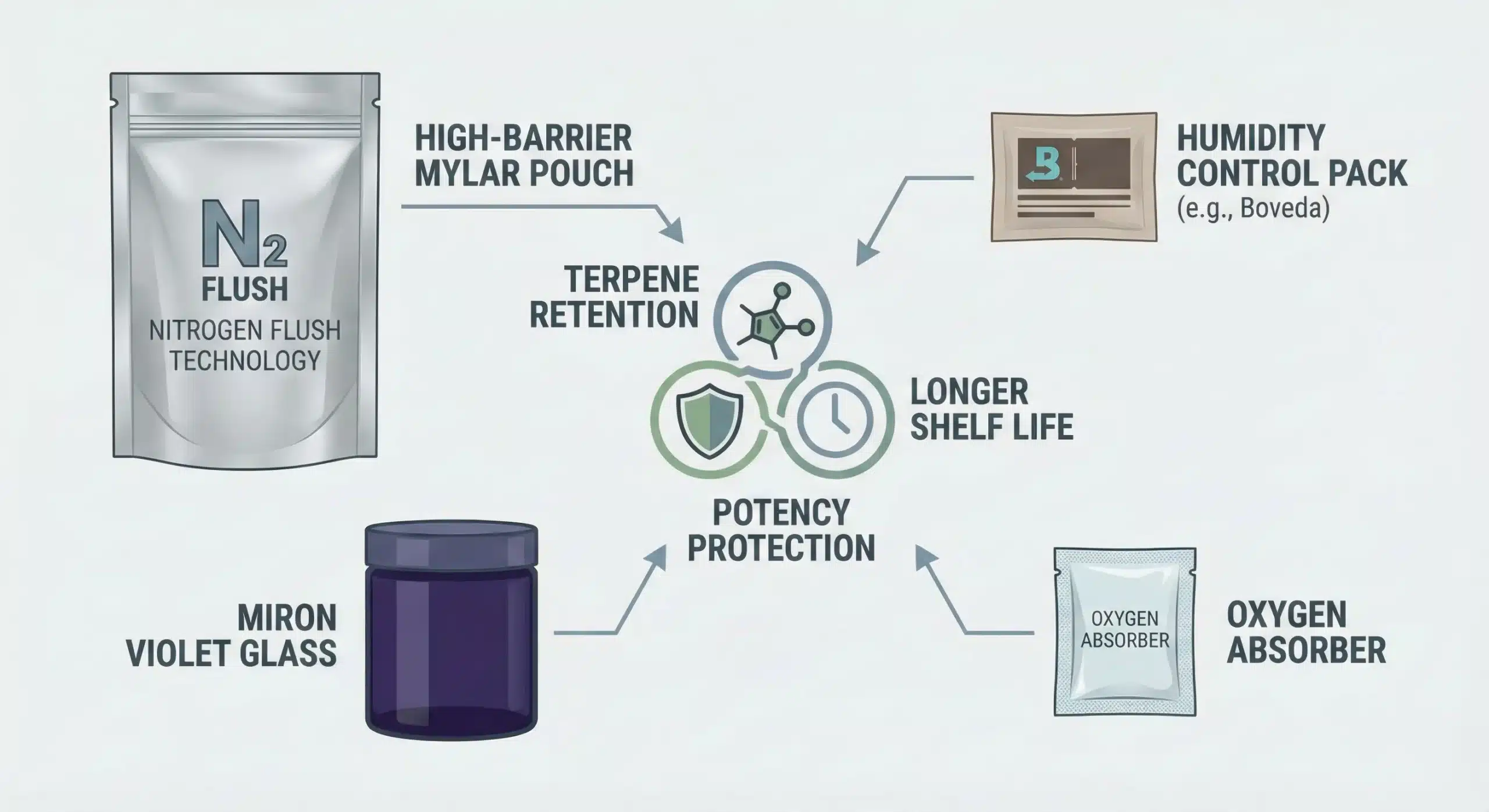

Preservation Technology That Actually Works

Keeping your cannabis flower fresh means controlling moisture, oxygen, and light. Here’s what works best:

- Humidity Control Packs: Brands like Integra Boost, Boveda, and Humidity Bead are popular because they keep moisture just right. These packs prevent your flower from drying out or getting too damp, which helps preserve terpenes and cannabinoids longer.

- Oxygen Absorbers & Nitrogen Purging: Oxygen breaks down THC and boosts CBN, which lowers potency. Using oxygen absorbers or flushing your packaging with nitrogen removes oxygen, slowing degradation and extending shelf life.

- Vacuum Sealing vs. Heat Sealing: Vacuum sealing pulls out air before sealing, protecting flower better than standard heat sealing alone. Heat sealing prevents air but doesn’t remove it, so vacuum-sealed packs tend to keep cannabis fresher for longer.

- Shelf-Life Testing Data: Real-world tests show THC levels hold up much better when combining humidity control with oxygen-limiting methods. For example, packages with Boveda packs and nitrogen flushing retained over 90% THC for 6+ months, while untreated packs dropped below 70% in the same time span.

Using the right preservation tech isn’t just about compliance — it’s about delivering quality product every time while keeping your brand reputation strong.

Branding & Design: Turning Packaging Into Marketing

Great cannabis flower packaging isn’t just about protection—it’s your brand’s handshake with customers. How your packaging looks and feels can make all the difference on crowded dispensary shelves.

Custom Printing Limits by Material

Different materials handle printing differently:

- Mylar bags work well with vibrant, full-color prints but can fade with poor-quality inks.

- Glass jars often have limited printing options and usually rely on labels or sleeves.

- Pop-top containers typically allow for simpler printing or sticker labels.

Make sure your design fits the material’s capabilities—this keeps your look sharp and professional.

Matte vs. Soft-Touch vs. High-Gloss Finishes

Finish matters:

- Matte gives a clean, modern vibe and reduces glare, making text easy to read.

- Soft-touch adds a smooth, premium feel that customers love to hold.

- High-gloss catches the eye with shine and pops under lights but can show fingerprints.

Choosing the right finish helps your packaging stand out and matches your brand’s style.

Spot UV, Foil Stamping, Embossing

These special effects add extra punch:

- Spot UV highlights logos or certain areas with shiny coating.

- Foil stamping brings metallic colors that look upscale and catch attention.

- Embossing creates a tactile, raised surface for logos or patterns.

Use these to create a premium feel without overdoing it.

Window vs. Fully Opaque Designs

Decide if you want customers to see the flower inside:

- Windows build trust by showing quality buds but can expose product to light.

- Opaque packaging protects from light damage and keeps your design clean and bold.

You might choose opaque with UV-blocking materials or a small window with protective films.

QR Codes, Strain Info, and Storytelling Space

Use packaging to tell your brand’s story:

- Add QR codes linking to lab results, grow information, or educational content—this builds trust and transparency.

- Include strain details like effects, terpene profiles, and origin to inform buyers.

- Reserve space for your brand’s story or mission—customers connect with authenticity.

Smart design turns compliant cannabis flower packaging into a powerful marketing tool that helps you build lasting relationships with your customers.

Cost Breakdown: What You’ll Actually Pay in 2026

When budgeting for cannabis flower packaging in 2026, understanding the real costs upfront is key. Here’s a quick look at per-unit prices for popular options, plus some hidden fees to watch out for.

Per-Unit Pricing Tiers

| Packaging Type | 1,000 Units | 10,000 Units | 50,000+ Units |

|---|---|---|---|

| Mylar Bags (custom printed) | $0.35 – $0.50 | $0.25 – $0.40 | $0.18 – $0.30 |

| Glass Jars (with CR lids) | $1.20 – $1.60 | $0.90 – $1.30 | $0.75 – $1.00 |

| Pop-Top Vials (bulk) | $0.45 – $0.65 | $0.35 – $0.50 | $0.28 – $0.40 |

Prices vary by material quality, printing complexity, and supplier location.

Hidden Costs to Consider

- Tooling and Setup Fees: Custom molds, specialized seals, or printed designs often come with upfront fees ranging from $500 to $3,000.

- Certification Testing: Child-resistant cannabis packaging must pass testing (CPSC, ASTM D3475), which can add $1,000+ depending on how many packaging types you certify.

- Minimum Order Quantities (MOQs): Some suppliers require orders of 5,000 units or more, which impacts cash flow.

- Shipping: Domestic suppliers may charge more but offer faster, reliable delivery versus overseas options with lower costs but longer lead times.

Budget vs. Premium Options

- Budget: Mylar stand-up pouches and basic pop-top vials offer affordability but may lack advanced preservation features.

- Premium: UV-blocking glass jars with certified child-resistant lids and nitrogen flushing come at a higher price but protect terpene profiles and THC content longer.

Understanding these cost layers helps you pick packaging that fits your budget without cutting corners on quality or compliance.

How to Choose the Right Supplier (Red Flags & Green Flags)

Picking the right cannabis flower packaging supplier can make or break your operation. Here’s how to spot a good one—and avoid headaches.

Questions to Ask Every Vendor

- Are your products child-resistant certified? (Look for ASTM D3475, CPSC, or ISO certification proof.)

- Can you provide samples? Check quality before buying large batches.

- What are your lead times? Faster turnaround keeps your supply chain flexible.

- Where are you located? Domestic suppliers usually mean quicker shipping and easier communication; overseas vendors might offer lower prices but longer waits.

- Do you offer custom printing? Important for branding on mylar bags or glass jars.

- What’s the minimum order quantity (MOQ)? Make sure it fits your budget and scale.

- How do you handle compliance? Your supplier should know current packaging laws in key states.

Red Flags to Watch For

| Red Flag | Why It Matters |

|---|---|

| No proof of CR certifications | You risk fines or product recalls. |

| Long or vague lead times | Could delay your product launches. |

| No sample or only low-quality samples | You can’t verify product quality. |

| Lack of transparency on MOQ or pricing | Could blow your budget unexpectedly. |

| Poor communication or slow replies | Difficult to resolve issues quickly. |

Green Flags You Want

| Green Flag | Benefit |

|---|---|

| Clear child-resistant compliance | Your packaging meets legal safety standards |

| Fast, consistent lead times | Keeps your operations running smoothly |

| Offers sustainable packaging options | Meets growing consumer demands |

| Custom printing and design flexibility | Helps your brand stand out on shelves |

| Positive reviews and references | Confirms reliability and product quality |

Domestic vs. Overseas Suppliers

- Domestic suppliers: Faster shipping, easier to verify certifications, often better at meeting state-specific regulations.

- Overseas suppliers: Usually more affordable but factor in longer shipping, customs delays, and harder quality control.

Certification Proof & Samples Matter

Always ask for certification documents to make sure packaging is truly child-resistant and compliant. Sampling before ordering large volumes helps avoid costly mistakes.

Top Cannabis Flower Packaging Suppliers (No Hard Sell)

Look for companies known for:

- Reliable mylar bags wholesale for flower with custom printing.

- Quality glass jars with CR lids and UV protection.

- Bulk pop top containers that pass ASTM and CPSC tests.

- Sustainable nitrogen flushed flower packaging options.

Doing your homework on suppliers ensures your cannabis flower packaging ticks all the boxes—legal compliance, preservation, and branding—without surprises.

Step-by-Step: Building Your Perfect Packaging Stack

Small Grower (<5,000 units/year)

If you’re a small grower, keeping costs low while staying compliant is key. Start with basic compliant cannabis flower packaging options like:

- Mylar bags wholesale for flower with child-resistant zippers (ASTM D3475 certified)

- Simple pop-top plastic vials for smaller batch sales

- Use humidity control packs like Boveda or Integra Boost to preserve freshness

- Focus on easy labeling to meet state-specific requirements without breaking the bank

Ordering in small batches keeps inventory flexible and reduces upfront costs. Look for suppliers that offer low minimum order quantities and free samples.

Mid-Size Brand (10K–100K units/year)

For mid-size brands, efficiency and branding matter more. Consider:

- Bulk purchasing cannabis flower glass jars with CR lids for a premium touch

- Custom printed mylar bags cannabis-style to stand out on shelves

- Vacuum-sealed or nitrogen flushed flower packaging to extend shelf life and preserve terpenes

- Durable, child-resistant cannabis packaging that balances ease for seniors and safety for kids

- Work with suppliers offering reliable lead times and certification proof to avoid compliance hiccups

Here, investing in branding elements like embossing or foil stamping can boost your product’s appeal and justify a higher price point.

Large Commercial Operation (100K+ units/year)

Large operations need scalable, cost-effective, and fully compliant solutions:

- Mix of rigid plastic containers and high-barrier films (7-layer Mylar) for preservation and compliance

- Advanced packaging tech like vacuum sealing and humidity control for cannabis storage in bulk

- Consider custom automated packaging lines and partnerships with domestic cannabis packaging suppliers USA

- Implement exit bags dispensary requirements and tamper-evident seals at high volume

- Sustainability counts: Explore sustainable cannabis packaging 2026 options like biodegradable films or PCR plastics to meet consumer demand and regulations

Bulk pricing and negotiated service contracts can significantly reduce per-unit packaging costs at this stage.

Downloadable Checklist (Bonus)

To simplify your packaging journey, I’ve included a downloadable checklist. It covers:

- Key compliance points for your state

- Packaging format choices by production size

- Essential preservation tools

- Branding and certification must-haves

- Supplier vetting questions

Use it to make sure your cannabis flower packaging stack fits your business needs perfectly, whether you’re just starting out or scaling fast.

Building the right packaging stack means balancing cost, compliance, preservation, and brand impact. With the right approach tailored to your size and goals, you’ll deliver a great product that stands out and stays fresh.

Future Trends in Cannabis Flower Packaging (2026–2028)

The cannabis packaging world is evolving fast, and growers and dispensaries need to stay ahead. Here’s what to watch for in the next few years:

-

Fully Compostable High-Barrier Films

Sustainability is no longer optional. Expect a rise in compostable films that protect your flower just like traditional Mylar or foil but break down naturally. These new materials block light, oxygen, and moisture while helping brands meet eco-friendly demands.

-

Smart Packaging with NFC & Freshness Indicators

Technology is making packaging smarter. NFC (Near Field Communication) tags will allow consumers to tap their phone and get strain info, lab results, or harvest details instantly. Freshness indicators embedded in packaging will show when flower quality drops, keeping customers safe and informed.

-

Reusable Container Programs

Reusability is gaining ground as dispensaries look to cut waste and improve loyalty. Expect more programs offering durable cannabis glass jars or metal tins that consumers can return or refill. These also boost brand value as they get reused long after purchase.

-

QR Codes for Lab Results & Seed-to-Sale Tracking

Regulations push for transparency. QR codes on packaging will link not just to lab test results but full seed-to-sale tracking info. This builds trust, simplifies compliance, and gives customers peace of mind about product safety.

Staying on top of these trends means you’ll future-proof your cannabis flower packaging—saving money, staying legal, and pleasing customers. The shift to tech-enabled, eco-friendly, and interactive packaging is already here—are you ready?