The numbers might surprise you – China’s cannabis packaging industry has 322 fitting manufacturers and 158 service providers. These options can be overwhelming to sort through.

The Pearl River Delta region leads China’s packaging industry. Yet finding reliable cannabis packaging suppliers remains a challenge. Our industry faces major obstacles from regulatory compliance to complex international shipping and higher tariff costs.

The search for dependable partners in China needs careful thought, whether you run a cannabis packaging company or need trusted manufacturers. The market looks different now compared to 2002 when the first fitting companies started. Today’s scene blends 2002-old companies with newer players that emerged in 2024.

Let us help you find and verify trustworthy cannabis packaging suppliers in China. You’ll learn to direct regulatory requirements and create lasting business relationships. The information you need follows next.

Understanding Chinese Cannabis Packaging Market

China’s cannabis packaging market holds a substantial 25% share of the Asia Pacific region [1]. The market shows great promise, especially when you have strong manufacturing infrastructure and skilled workers ready to go.

Current market landscape

China’s cannabis packaging sector continues to grow steadily, with a focus on medical cannabis packaging solutions [2]. The global cannabis packaging market, valued at USD 2.64 billion in 2023, is set to reach USD 13.17 billion by 2030 [3]. China plays a vital role in this growth thanks to its 30-year-old manufacturing capabilities and export-driven operations.

Key manufacturing regions

China’s packaging facilities are spread strategically across the country. The eastern regions have always been the main production hubs [4]. You’ll find most packaging manufacturers concentrated in the Pearl River Delta region. Western China has also become a thriving manufacturing zone, where facilities have earned proper certifications to operate [4].

Types of suppliers available

Chinese cannabis packaging suppliers come in three main types:

-

Manufacturing specialists who focus on specific packaging types (rigid containers, flexible packaging)

-

Full-service providers who deliver integrated solutions including filling, sealing, and labeling

-

Custom packaging developers who create brand-specific solutions

These suppliers excel at producing various packaging materials, from glass and metal to eco-friendly options [5]. The rigid packaging segment dominates with 78% of the market share, especially in plastic bottles and glass jars [5]. Flexible packaging is growing fast, with a projected growth of 25% during 2024-2029 [5].

The market focuses heavily on child-resistant packaging solutions, eco-friendly materials, and meeting international standards [6]. Chinese manufacturers adapt quickly to new requirements and create specialized solutions for different cannabis products, from flowers to concentrates [5].

Essential Supplier Verification Steps

You need to verify Chinese cannabis packaging suppliers carefully to ensure they run legitimate businesses and meet quality standards.

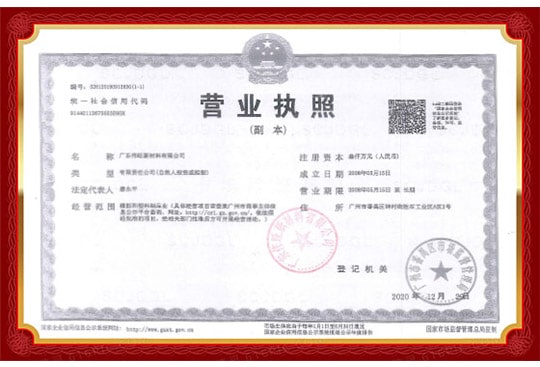

Business license verification

Chinese suppliers must have an 18-digit business registration number from their government [7]. Their business license needs to show the company’s official name, entity type, registered address, legal representative, and what they do [7]. You can check these documents through the National Enterprise Credit Information Publicity System (NECIPS), which keeps all official registration records [7].

Manufacturing capability assessment

A complete factory audit is the life-blood of evaluating suppliers. Professional auditors look at the factory’s reliable infrastructure, how well they maintain equipment, and their production processes [8]. They focus on:

-

Production capacity and technical capabilities

-

Process flow and working instructions

-

Storage conditions and inventory management

-

Employee training systems and skill levels

-

Quality control procedures [8]

Quality certification requirements

Cannabis packaging suppliers must prove they meet specific quality standards. They need certification from ASTM-approved testing facilities for child-resistant packaging [9]. The suppliers should provide:

-

Food-grade certification for packaging materials

-

Certificate of compliance for component specifications

-

Child-resistant packaging certification where applicable [10]

Strict regulations mean suppliers must keep proper documentation that proves they follow food safety standards and quality management systems [11]. You also need to get a full picture of the supplier’s quality control systems, documentation procedures, and how they keep records [8].

Evaluating Supplier Samples

Getting and checking samples plays a key role when you choose cannabis packaging suppliers from China. Physical samples show you exactly what manufacturers can do and their quality standards.

Sample request process

Your suppliers should give you both physical and digital samples to check [12]. Physical samples let you feel the material quality, see the design elements, and test product fit firsthand. When you ask for samples, make sure you spell out exactly what you need in terms of packaging materials and sizes [13].

You’ll need about 3-5 days to check the samples properly [13]. During this time, you should test how well they hold up, how durable the materials are, and how good the printing looks. The best way to test these packages is with real products or 3D-printed versions [14].

Quality testing checklist

A full quality check focuses on these key points:

-

Structural Assessment: Check if the packaging can protect what’s inside during shipping [15]

-

Material Compatibility: Look for any chemical reactions with cannabis products [16]

-

Print Quality: Make sure all branding and required labels look consistent [15]

-

Functional Testing: Check that child-resistant features work and the package is easy to use [16]

-

Environmental Testing: Put samples through different conditions like changes in humidity and temperature [15]

You should keep detailed notes during all your tests. Just the child-resistant packaging tests cost about USD 8,000 and need 400 samples [17]. This might seem expensive, but it’s worth it. If you need to remake molds because of failed tests, you’ll pay between USD 2,000 to USD 50,000 [17].

Good records of your sample tests will give you quality standards to measure against for future orders. Working with certified testing labs makes sense because they have the right equipment and know exactly how to validate packaging [18].

Building Long-term Supplier Relations

Building strong partnerships with cannabis packaging suppliers in China needs a strategic approach that lines up clear communication with mutual understanding.

Communication best practices

We depended on regular, structured communication to build successful relationships with Chinese suppliers. Written agreements are the foundations of every interaction that ensure both parties have clear documentation of terms, pricing, and quality standards [19]. Detailed records of all discussions and decisions work better than verbal agreements.

Scheduled check-ins with regular updates help prevent delays and spot potential issues early. Chinese suppliers value transparency about business needs and future goals. This makes shared planning of their services with expectations easier [19].

Contract negotiation tips

Understanding cultural nuances is a vital part of successful negotiations. Chinese business culture puts relationships before deals [20]. Face-to-face meetings and social interactions are nowhere near optional – they help build stronger partnerships.

To name just one example, see these key elements in drafting contracts:

-

Clear quality specifications and standards

-

Detailed production timelines

-

Intellectual property protection clauses

-

Dispute resolution procedures [21]

Payment terms and guarantees

Payment structures need careful thought to protect both parties’ interests. The most balanced approach uses a 30% original deposit, with 70% payment after quality control inspection [22]. Letters of credit are a great way to get additional security, though fewer suppliers accept this payment method.

Whatever payment terms you choose, all agreements must include quality guarantees and clear procedures to handle defects or delays. Custom packaging projects need proper documentation to secure intellectual property rights [23].

Conclusion

Business owners need reliable cannabis packaging suppliers in China. The search requires research and a methodical process. Quality assessments and proper verification steps help build strategic collaborations that lead to long-term success.

The path to success begins when you verify suppliers properly. You should check business licenses and assess manufacturing capabilities. Getting samples becomes the most important step because it lets you test quality firsthand before making big commitments.

Suppliers thrive on clear communication, well-laid-out contracts, and balanced payment terms. Chinese suppliers place high value on face-to-face meetings and building relationships. Personal connections pave the way to successful partnerships.

Your choice of supplier affects product quality, regulatory compliance, and business reputation directly. Take time to verify credentials, test samples, and set up clear communication channels. This approach helps create lasting partnerships with dependable Chinese manufacturers.

References

[1] – https://www.grandviewresearch.com/industry-analysis/cannabis-packaging-market-report\

[2] – https://www.gminsights.com/industry-analysis/cannabis-packaging-market\

[3] – https://www.coherentmarketinsights.com/industry-reports/cannabis-packaging-market\

[4] – https://mjbizdaily.com/in-wake-of-coronavirus-cannabis-firms-look-for-packaging-outside-of-china/\

[5] – https://www.mordorintelligence.com/industry-reports/cannabis-packaging-market\

[6] – https://www.levapack.com/cannabis-packaging/\

[7] – https://www.supplyia.com/verify-chinese-supplier/\

[8] – https://www.hqts.com/china-factory-audit/\

[9] – https://assurpack.com/keep-cannabis-packaging-compliant/\

[10] – https://cannabisindustryjournal.com/feature_article/how-to-vet-suppliers-in-cannabis-product-manufacturing/\

[11] – https://www.trade.gov/knowledge-product/china-labelingmarking-requirements\

[12] – https://marijuanapackagingsolution.com/is-alibaba-the-one-and-only-channel-to-source-cannabis-packaging-supplies-from-china/\

[13] – https://jingsourcing.com/customize-product-packaging-in-china-a-complete-guide/\

[14] – https://mjbizdaily.com/how-to-find-a-cannabis-packaging-supplier-and-what-to-avoid/\

[15] – https://www.paramountglobal.com/knowledge/test-custom-packaging-samples/\

[16] – https://adeptpackaging.com/blog/considerations-for-packaging-risk-assessment/\

[17] – https://mjbizdaily.com/marijuana-packaging/\

[18] – https://www.paramountglobal.com/knowledge/guide-to-packaging-testing-methods/\

[19] – https://sinotradesourcing.com/the-ultimate-guide-to-building-long-term-relationships-with-chinese-suppliers/\

[20] – https://www.mgtrading.com/supplier-relationships-in-china-keys-to-long-term-success/\

[21] – https://www.cosmosourcing.com/blog/how-to-negotiate-manufacturing-contracts-in-china-top-tips-from-experts\

[22] – https://harris-sliwoski.com/chinalawblog/china-manufacturing-and-the-huge-impact-of-payment-terms/\

[23] – https://harris-sliwoski.com/chinalawblog/manufacturing-in-china-minimizing-your-risks-by-doing-things-right/