If you’re building a cannabis brand in 2025 and you’re still treating pre-roll tubes like an afterthought, you’re leaving money (and probably compliance risk) on the table.

Pre-rolls now make up 35–50% of flower sales in mature markets. That means your tube isn’t just a container — it’s your first impression, compliance shield, odor-proof vault, and mini billboard all in one.

In this guide to Pre-Roll Tubes 101, you’ll see exactly what separates cheap, generic “doob tubes” from child-resistant, smell-proof, sustainable, brand-building packaging that buyers actually remember. We’ll break down materials, sizes, CR certifications, branding options, pricing reality, and how to avoid getting burned by the wrong supplier.

If you want pre-roll packaging that keeps product fresh, passes lab and state inspections, and actually helps you sell more — not just check a box — keep reading.

What Are Pre-Roll Tubes and Why Do They Matter?

Pre-roll tubes are hard-shell, child-resistant pre-roll containers designed to hold and protect individual joints or multi-packs. Think of them as the armor for your pre rolls: they keep your product safe, compliant, fresh, and on-brand from your facility to the consumer’s pocket.

Core Functions of Pre-Roll Tubes

1. Protection & Freshness

- Rigid tube walls prevent crushing, bending, and shattering of delicate pre-rolls.

- Tight seals support odor proof pre-roll packaging and help maintain terpene profile.

- Compatible with humidity packs to keep joints from drying out or going stale.

2. Compliance & Safety

- Designed as child resistant pre-roll tubes that meet CPSC, ASTM, and state-level rules.

- Support tamper-evident seals and lot/COA labeling for full cannabis pre-roll packaging compliance.

- Odor control and opaque options help you stay on the right side of local regulations.

3. Branding Power

- Tubes are visible, handled, and opened repeatedly – perfect as mini billboards.

- Ideal for custom pre-roll tubes with logo, strain info, QR codes, and brand storytelling.

- Consistent tube design becomes a recognizable brand asset at retail and in the consumer’s hand.

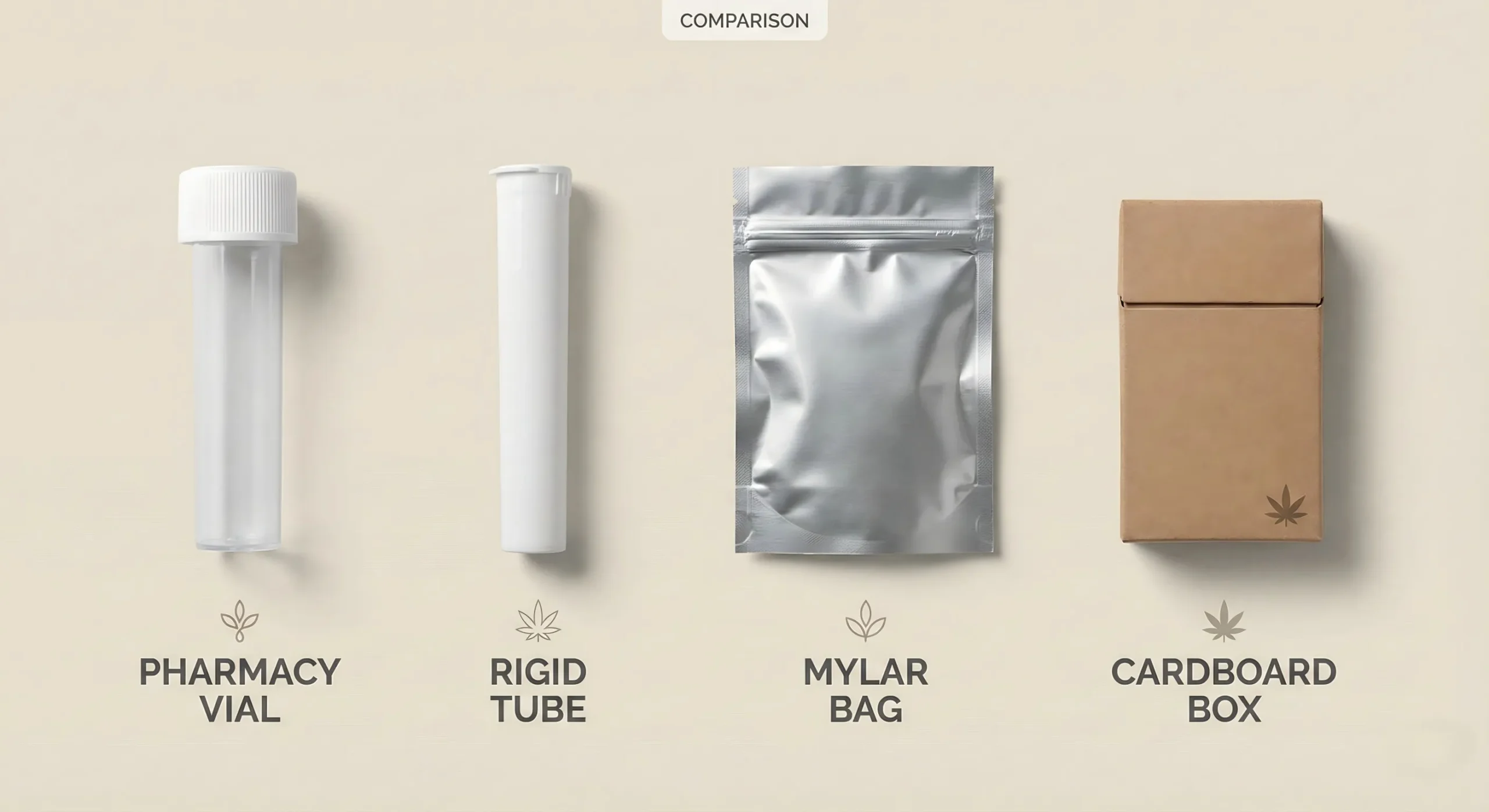

Tubes vs. Vials, Mylar Bags, and Boxes

Pre-roll tubes vs. vials

- Vials are often pharmacy-style and generic; tubes are built for joints, not pills.

- Tubes offer better fit, odor containment, and child resistant pre-roll tube packaging than most standard vials.

Pre-roll tubes vs. mylar bags

- Mylar bags win on flat shipping and low cost, but:

- They can crush or bend pre-rolls.

- They’re less discreet in pockets and easier to wrinkle or tear.

- Tubes provide rigid, smell proof doob tubes performance and a more premium in-hand feel.

Pre-roll tubes vs. boxes

- Boxes are great for shelf presence, but:

- They usually require an inner tube or tray for real protection.

- They add cost and complexity for pre roll packaging logistics.

- Tubes stand alone as single-unit or multi-pack pre roll tube packaging, with direct print branding and strong durability.

If you sell pre-rolls at any serious volume, pre roll tubes for cannabis aren’t an accessory—they’re infrastructure. They decide how your product survives shipping, passes compliance checks, and shows up in your customer’s pocket tomorrow.

Key Features Every Cannabis Brand Should Demand

When I source or design pre roll tube packaging for cannabis, I look at five non‑negotiables: safety, smell, freshness, durability, and security. If your supplier can’t prove these, don’t buy.

1. Child-Resistant Pre-Roll Tubes (Real Certification Only)

Your pre roll tubes must be certified child resistant, not just “CR-style”.

What to insist on:

- CPSC / ASTM D3475 / ISO 8317 test reports

- State-specific approvals (especially CA, CO, MI, NY, FL)

- Clear instructions for adults, but hard for kids to open

- Matching lot numbers on packaging and certificates

If a supplier can’t show legit lab reports, walk away. You can see how serious regulators are about packaging on our cannabis packaging compliance overview.

2. Odor-Proof / Smell-Proof Performance

Odor leakage kills brand trust and gets dispensaries in trouble.

Key points for smell proof doob tubes:

- Tight snap or threaded seal that doesn’t deform after multiple uses

- Material matters: PP and PET with proper wall thickness seal better than cheap, thin plastics

- Lab-tested odor control is ideal; at minimum, do in-house “smell tests” with loud strains

Look for suppliers who specialize in odor proof pre roll tubes for dispensaries, not just generic plastic packaging.

3. Moisture Control & Freshness

Dry joints = bad reviews. Overly moist = mold risk.

What to look for:

- Tubes that close airtight to hold humidity

- Inner space that fits mini humidity packs (e.g., 0.5–1g packs) for premium SKUs

- Materials that don’t warp in heat and keep the seal consistent

Ask for a 3–6 month shelf-life test from your supplier, especially for pre roll tubes for cannabis stored in hot or humid markets.

4. Shatter-Proof Durability & Drop Tests

If your tubes crack, your brand looks cheap.

Quality CR pre-roll tube durability standards:

- Survive multiple 1–1.5m drops onto hard floor without cracking

- Thick enough walls to protect glass-tipped or infused pre-rolls

- Flex-but-don’t-break design for PP and PET tubes

Some brands also follow similar drop expectations to rigid containers used for 3.5g pop-top packaging, which is a good durability benchmark.

5. Tamper-Evident Options

Tamper-evident = safety + compliance + consumer trust.

Popular tamper-evident features:

- Perforated shrink bands around cap and body

- Break-off tabs or tear-away rings on the cap

- Security labels that tear if removed

For wholesale pre roll tubes bulk, I always recommend ordering them ready for tamper-evident sealing, so you’re not improvising later.

Quick Feature Checklist

| Feature | Why It Matters | What To Demand |

|---|---|---|

| Child-resistant | Legal compliance & safety | CPSC / ASTM / ISO certificates |

| Odor-proof | Dispensary comfort & consumer privacy | Tight seals, lab/field smell tests |

| Moisture & freshness | Flavor, burn quality, shelf life | Airtight design, humidity pack compatibility |

| Shatter-proof durability | Protects product, reduces returns | Drop-test performance data |

| Tamper-evident options | Consumer trust & regulatory protection | Shrink bands, tear tabs, or security labels |

If your pre roll tubes hit all five, you’re in a strong place for 2026. If they don’t, it’s time to upgrade your supplier.

Materials Breakdown: Best Pre-Roll Tubes for 2026

When I choose pre roll tubes for cannabis, I look at four things first: cost, sustainability, durability, and brand image. Here’s how each material stacks up in 2026.

Polypropylene (PP) Pre Roll Tubes – The Workhorse

PP is still the industry standard for child resistant pre-roll tubes.

Pros:

- Lowest cost at scale – perfect for wholesale pre roll tubes bulk

- Strong, flexible, and shatter-resistant

- Easy to color match, brand, and add pop top or squeeze top CR closures

- Widely accepted by testing labs and regulators

Cons:

- Not naturally eco-friendly unless blended with PCR (recycled) content

- Can feel “cheap” for premium brands if the finish and printing are basic

Best for: value-driven brands, large MSOs, and dispensaries needing odor proof pre-roll packaging with tight margins.

PET & rPET Pre Roll Tubes – The Eco Upgrade

PET and recycled rPET are driving the eco-friendly shift in pre roll tube packaging.

Pros:

- Higher clarity (for translucent or clear tubes)

- rPET adds a strong sustainability story (post-consumer recycled)

- Lighter weight vs. glass with lower breakage risk

- Good for brands focused on sustainable pre-roll tubes

Cons:

- Slightly higher cost than PP

- Must confirm CR performance and pre roll tube packaging compliance with your market

Best for: brands that want a visible “recycled” story without jumping to glass.

Glass Pre Roll Tubes – Premium, But With Trade-Offs

Glass pre-roll tubes are all about luxury perception.

Pros:

- Strong premium feel – great for top-shelf or infused pre-rolls

- Pairs well with cork or CR caps for a high-end look

- Excellent smell proof doob tubes performance when paired with quality caps

Cons:

- Heavier, higher shipping costs, and break risk

- More expensive per unit than PP/PET

- Not ideal for rough handling or mail-order markets

Best for: luxury brands, limited drops, and SKUs where packaging is part of the price.

Biodegradable & Compostable Tubes – PLA & Plant Blends

Biodegradable joint tubes made from PLA or rice paper blends are gaining traction but need careful vetting.

Pros:

- Strong eco marketing angle if backed by real certifications

- Plant-based materials appeal to conscious consumers

- Great talking point on your custom pre roll tubes with logo

Cons:

- Heat sensitivity and shelf-life concerns in hot climates

- Not all “biodegradable” claims are real – you must avoid greenwashing

- May cost more and require specific storage/handling

Best for: niche eco-focused brands willing to pay more and educate consumers.

Cost vs. Sustainability vs. Luxury: What Actually Wins?

If I simplify it for most cannabis brands:

- Best cost + reliability: PP child resistant pre roll tubes

- Best sustainability story for the price: rPET pre roll tubes with PCR content

- Best luxury perception: Glass tubes with premium CR closures

- Best eco-niche positioning: Certified compostable / biodegradable pre roll packaging, with clear claims

Most global brands right now are choosing:

- PP + PCR content as their baseline, then

- Upgrading key SKUs with rPET or glass for premium lines.

If cost pressure is heavy, pairing smart materials with better design and branding is often the fastest way to reduce packaging spend without killing your image, similar to how we approach cost-optimized custom cannabis packaging in other categories (reducing cannabis packaging costs while protecting quality).

Child-Resistant Pre-Roll Tubes: How Each Mechanism Really Performs

When you’re picking child resistant pre-roll tubes, the closure system is what makes or breaks both compliance and customer experience. I look at every CR mechanism through three filters: certification potential, ease of use for adults, and production practicality.

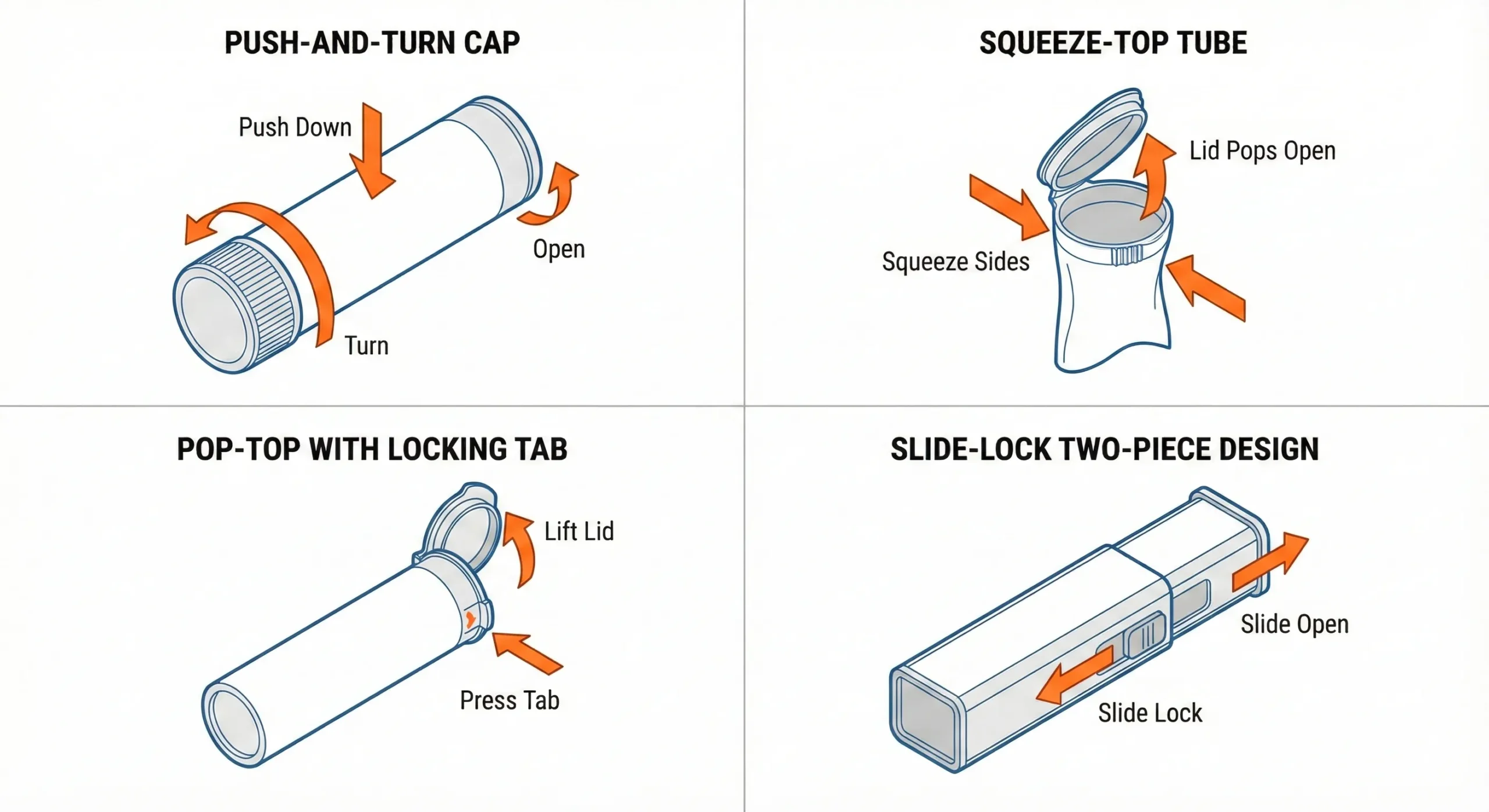

Push-and-Turn (Classic Child-Resistant Cap)

This is the same motion people know from pharma bottles.

How it works

- User pushes the cap down and twists at the same time

- Usually a threaded PP or PET tube with a CR closure

Why brands use it

- Strong track record for CPSC / ASTM / ISO child-resistance

- Easy to pass state-level cannabis pre-roll packaging compliance testing

- Feels familiar to older and medical consumers

Consumer feedback

- High perceived safety, especially for households with kids

- Some complaints from seniors or users with low grip strength

- Great for premium pre-roll packaging where “serious” safety is part of the brand story

Squeeze-Top / Pinch-to-Open Doob Tubes

Very popular in U.S. dispensaries for single pre-roll tubes.

How it works

- User squeezes two marked points on the tube to release the cap

- Often used on 109mm pre-roll tubes and dogwalker sizes

Why brands use it

- Fast, one-handed open for regular consumers

- Works well on automated pre-roll filling and capping lines

- Clean look for custom pre-roll tubes with logo and full-wrap labels

Consumer feedback

- Loved for convenience and speed

- Some users complain that cheap versions lose tension and become less CR over time

- When engineered right and properly certified, this is one of the best-performing smell proof doob tubes styles

Pop-Top with Locking Tab

Think classic “pop-top” joint tube, updated for cannabis regulations.

How it works

- User pushes or presses a locking area until the cap “pops” up

- Some designs integrate a tab that must be pressed in first (to qualify as CR)

Why brands use it

- Very fast on the retail side for budtenders and producers

- Strong “pop” experience that customers associate with freshness

- Great billboard space for odor proof pre-roll packaging with bold branding

Consumer feedback

- High satisfaction for speed and fun factor (“that pop feels good”)

- Concerns when non-certified pop-tops are used in strict markets

- If the seal is well designed, odor control is solid; if not, you’ll see odor leakage complaints quickly

Slide-Lock and Two-Piece CR Designs

These are more advanced, often used for pre-roll multi pack tubes or hybrid box/tube formats.

How it works

- User slides a tray or inner tube out while pressing or aligning a lock

- Can combine two-step actions (press + slide, pinch + slide)

Why brands use it

- Great for multi-pack pre-roll packaging (3-pack, 5-pack, 2g/3g formats)

- Feels premium and “techy,” ideal for design-focused brands

- More room for strain info, QR codes, and storytelling on the outer shell

Consumer feedback

- Very high perceived value and uniqueness

- Some first-time confusion if instructions aren’t printed clearly

- Once understood, users rate them highly for both safety and reusability

What Real-World Testing and Data Show

From our own projects and certification work, plus lab partners:

- Push-and-turn:

- Consistently strong pass rates in formal CR tests

- Slightly higher failure rates in senior-friendly usability tests

- Squeeze-top:

- Good balance of CR and usability when tension and wall thickness are dialed in

- Cheap imports often fail CR pre-roll tube certification because kids can deform them too easily

- Pop-top with locking tab:

- Passes most U.S. state standards when the locking feature is properly engineered

- Performance drops if the hinge or tab wears out after repeated use

- Slide-lock / two-piece:

- Excellent child-resistance in lab testing because of the multi-step motion

- Requires precise tooling and QC; poor tolerances = failed tests

If you want a deeper dive into what labs actually test for in CR cannabis packaging, I’d recommend reviewing the components of child-resistant packaging for cannabis breakdown we published at hemployd.

How I Recommend You Choose

- Need a safe, no-drama option for most markets?

→ Go push-and-turn or certified squeeze-top tubes. - Want a fun, fast retail experience with strong shelf presence?

→ Use pop-top with locking tab for single joints. - Launching a premium multi-pack line in strict markets?

→ Invest in a slide-lock / two-piece CR system and proper lab certification.

Whatever mechanism you pick, don’t trust a PDF claim alone. Ask suppliers for:

- Current CPSC / ASTM / ISO CR certificates

- Market-specific compliance reports (California, Canada, etc.)

- Real samples you can test with your own team and customers before committing to wholesale pre-roll tubes in bulk.

Size Guide for Pre-Roll Tubes: Match Tube to Your Joint, Every Time

Picking the right pre-roll tube size isn’t guesswork – it’s math. If the tube is too short, your tips bend. Too wide, and joints rattle, break, and stink up the box. Here’s how I size pre roll tube packaging for brands that care about fit, freshness, and look.

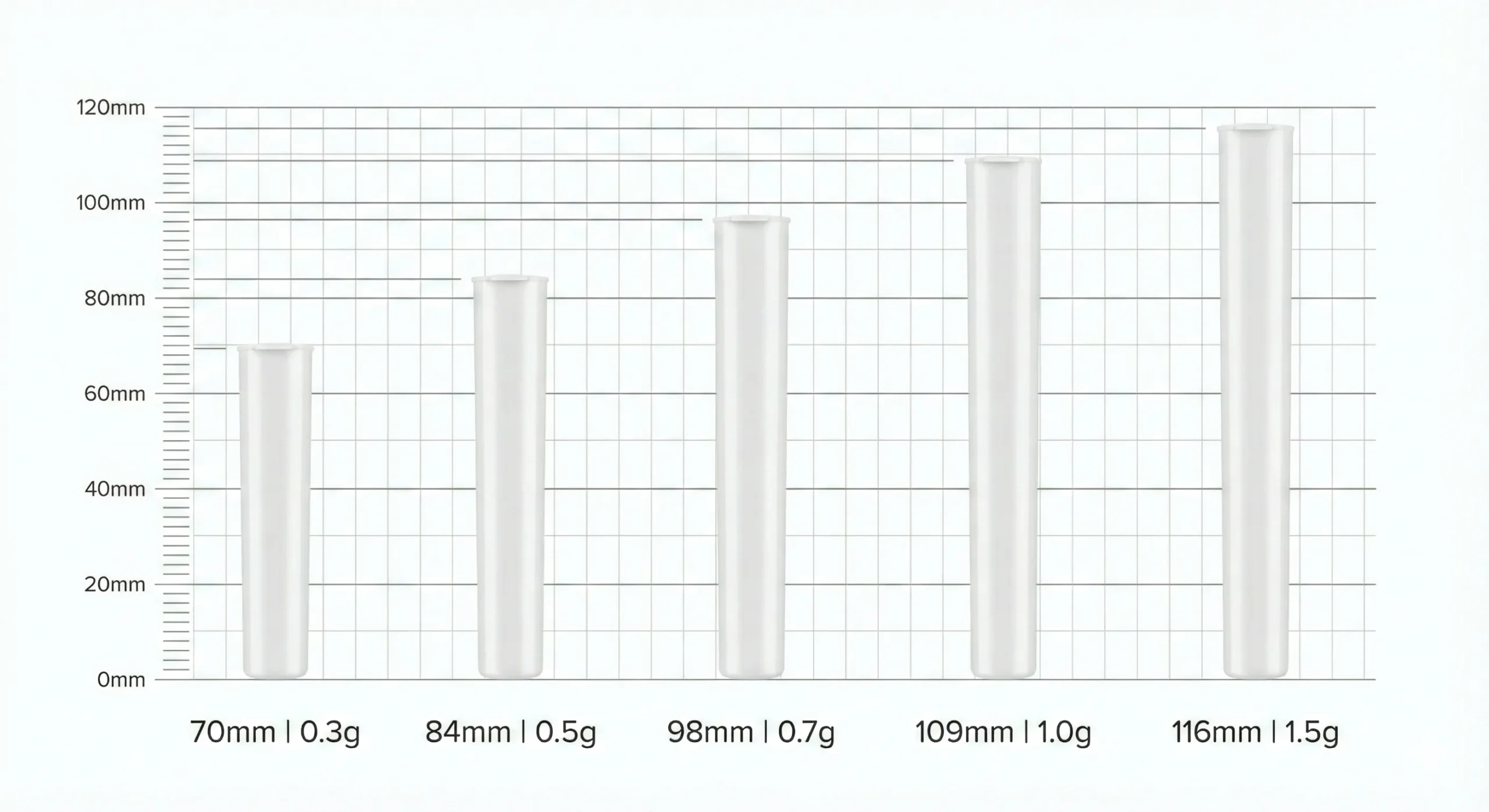

Standard Pre-Roll Tube Sizes (Length)

These are the most common pre roll tube sizes for cannabis:

- 70mm – Minis / dogwalkers, 0.25–0.35g

- 78mm – Slim short pre-rolls, 0.3–0.5g

- 84mm – “Cig-style” pre-rolls, common in value packs

- 90mm – Stubby 1g or fat 0.5g joints

- 98mm – Classic 0.75–1g pre-roll, great for most markets

- 109mm – King-size pre-roll tube (the 109mm pre-roll tubes everyone asks for)

- 116mm – Extra-long cones, infused or premium pre-rolls

- Dogwalker size – 50–70mm, microdose and multipack formats

- King-size – Usually 109–116mm, 1g+ or infused pre-rolls

If you’re new, I usually tell brands: start with 98mm or 109mm unless your format is very specific.

Single vs Multi-Pack Pre-Roll Tubes

Think about how your consumer actually smokes:

- Single tubes

- 0.5g mini / standard single

- 1g classic single – the best pre roll tubes for most dispensaries

- Multi-pack pre-roll tubes

- 2g (3 x 0.5g or 2 x 1g minis)

- 3-pack (0.5–0.75g joints)

- 5-pack (dogwalkers or slims; use a wider diameter so they don’t crush)

For multi-pack pre-roll tubes, I always mock up a physical fit test before we confirm tooling. Automated filling and packing will expose bad sizing fast.

Diameter Options (How Wide Should Your Tube Be?)

Diameter is what decides if your joint is snug or sloppy:

- 16mm – Slim singles, 0.3–0.75g

- 19mm – Standard 1g pre-roll tubes, most common

- 20mm – Slightly wider for infused or fatter cones

- 22mm – Multi-pack tubes (3–5 pre-rolls) or chunky infused sticks

Rule of thumb:

- Slim, single pre-rolls → 16–19mm

- King-size or infused → 19–20mm

- Multi-packs → 20–22mm

If you’re building out a full line of pre-roll packaging, it’s worth aligning tube sizes with your other compliant cannabis packaging choices so everything feels consistent across the brand. I walk a lot of brands through sizing, testing, and compliance in our breakdown of what cannabis packaging really needs to do, and the same logic applies here: tight fit, no odor leaks, and zero product damage.

Branding & Customization Options That Sell

When it comes to pre roll tube packaging, your design is doing the selling long before a budtender speaks. If your tube looks generic, you’re losing shelf power. Here’s how I approach branding for custom pre roll tubes with logo that actually move product.

Full-Color Digital Printing vs. Labels

Digital printing is what I recommend for most brands:

| Option | Pros | Cons | Best For |

|---|---|---|---|

| Full-color digital print | Edge-to-edge art, sharp details, no peeling | Slightly higher unit cost on small runs | Premium & mid-tier brands |

| Pressure-sensitive labels | Lower upfront cost, quick to change designs | Peels, wrinkles, looks “cheap” faster | Test drops, small-batch collabs |

| Shrink sleeves | 360° coverage, bold colors, tamper-evident look | Needs more setup, can feel “plasticky” | Loud, highly visual brands |

If you’re already investing in wholesale pre roll tubes bulk, cutting corners on the print is the fastest way to make premium flower look low-end.

Custom Logo Embossing & Debossing

If you want to look like a real player, add logo embossing or debossing directly on the tube or cap.

- Embossed: Logo raised from the surface – more tactile, premium feel.

- Debossed: Logo pressed in – subtle, more “design” driven.

These work especially well on matte and soft-touch finishes where touch matters. I use them for:

- Flagship strains

- Limited drops

- VIP / collab SKUs

They cost more upfront (tooling), but the perceived value jump on shelf is huge.

Matte, Gloss, and Soft-Touch Finishes

Finish changes everything, even on simple child resistant pre roll tubes:

| Finish | Look & Feel | Best Use Case |

|---|---|---|

| Matte | Modern, low glare, premium | Craft, small-batch, connoisseur lines |

| Gloss | Bold, shiny, high-contrast colors | Rec-heavy markets, loud brand identities |

| Soft-touch | Velvety, super premium in-hand feel | Top-shelf SKUs, gift-worthy packaging |

I like using soft-touch on odor proof pre roll packaging because the feel matches the premium promise: if it feels expensive, people assume what’s inside is better too.

QR Codes, Strain Info & Storytelling Space

Don’t waste your tube real estate. Treat it like a mini information hub:

- QR codes

- COAs and lab results

- Growing practices & sustainability info

- Loyalty programs or drop calendars

- Strain info

- Strain name + type (Indica/Sativa/Hybrid)

- THC/CBD %, terp highlights

- Intended experience (focus, chill, sleep)

- Storytelling space

- 1–2 punchy lines about your brand or strain origin

- Icons for key features (organic, sun-grown, solventless)

If you’re already building SKUs in bags or jars, keep your branding system aligned across formats. A strong, consistent look from pre roll packaging to flower jars builds trust faster than any discount.

Case Study: Tubes as Mini Billboards

Here’s how top brands turn smell proof doob tubes into walking ads:

Example setup:

- 109mm matte black pop top pre roll tubes

- Full-wrap digital print in brand color system

- Debossed logo on the cap

- Side panel with:

- Strain name in big type

- QR to lab results

- Tiny brand story: 1–2 sentences only

Why it works:

- At a distance: bold color + clear logo = instant recognition in the case

- In-hand: soft-touch + deboss = premium feel → easier to justify higher price

- At home: customers keep and reuse the tube, which means your brand stays in their pocket instead of going in the trash right away.

If you’re serious about scaling your SKU lineup and keeping your packaging efficient across formats, it’s smart to align tubes with your broader system of custom cannabis packaging so your brand feels like one family on shelf. For example, I use the same design rules we apply to our custom cannabis flower packaging to keep pre-rolls instantly recognizable in any market.

Dial in your tube branding once, then let it work as your cheapest, most consistent “billboard” inside every dispensary you enter.

Sustainability in 2026: What Brands Actually Want

Consumers are calling out greenwashing now, so pre roll tubes need to back up the “eco” claim with real data, not just a green cap and buzzwords.

PCR & Ocean-Bound Plastic Pre Roll Tubes

For most cannabis brands, the sweet spot in 2026 is PCR (post-consumer recycled) pre roll tubes and ocean‑bound plastic options:

- PCR pre roll tubes

- Cut virgin plastic use while keeping the same durability and CR performance.

- Work great for child resistant pre roll tubes and automated filling.

- Ideal if you want “sustainable pre roll tubes” without risking failures in drop tests or odor control.

- Ocean-bound plastic tubes

- Made from plastic collected near coastlines before it hits the ocean.

- Strong story for brands that lean heavily into climate and ocean protection.

- Pairs well with transparent impact messaging and carbon reporting.

If you’re learning how child-resistant packaging ties into responsible cannabis branding, it’s worth looking at how strict markets treat safety and sustainability together in child resistant cannabis packaging rules.

Fully Biodegradable & Compostable Pre Roll Tubes

“Biodegradable joint tubes” sound perfect, but only if they actually break down and still pass compliance:

- Look for certified compostable materials (e.g., PLA blends) with lab data.

- Confirm they hold a seal for odor proof pre roll packaging and don’t warp in heat.

- Use them more for premium SKUs or local markets that already have composting infrastructure.

Carbon-Neutral & Low-Impact Options

If you’re not ready to switch materials completely, you can still reduce impact:

- Choose lightweight designs to cut shipping emissions.

- Work with suppliers that can offer carbon-neutral programs or verified offsets.

- Prioritize efficient manufacturing and regional warehousing to reduce freight miles.

How to Market “Green” Pre Roll Packaging (Without Greenwashing)

To sell “eco” pre roll tube packaging and stay credible:

- Be specific, not vague

- Say “made with 50% PCR plastic” instead of “eco-friendly tube.”

- Mention certifications: FSC, ASTM D6400, EN 13432, etc., when relevant.

- Show proof

- Ask suppliers for material data sheets, test reports, and LCA summaries.

- Share real numbers when possible (recycled content %, CO₂ saved per million tubes, etc.).

- Be honest about trade-offs

- If a biodegradable tube has a shorter shelf life, say so.

- If you only use PCR on certain SKUs, don’t imply it’s your entire lineup.

- Keep it simple for the shopper

- Use clear icons: “Recycled Plastic,” “Compostable Where Facilities Exist,” “Made From Ocean-Bound Plastic.”

- Add a short line on the label or carton: “This child resistant pre roll tube contains 30% post-consumer recycled plastic.”

Brands that mix real sustainability upgrades with transparent communication win long term. That’s exactly how we position our own sustainable pre roll tubes: tested for CR, odor-proof, automation-friendly—then optimized for lower impact, not the other way around.

Compliance Checklist for Pre-Roll Tubes by Major Market

If you’re selling pre-rolls in 2026, your pre roll tube packaging has to be built around compliance first, branding second. Here’s the quick checklist I use market by market.

U.S. Cannabis Pre-Roll Packaging Compliance

Applies to: California, Colorado, Michigan, Illinois, New York, Florida (and most other legal states).

Core requirements for child resistant pre roll tubes:

- CR certification:

- Must pass CPSC 16 CFR 1700 child-resistant protocol.

- Look for ASTM D3475 and/or ISO 8317 references on test reports.

- Ask for a pass/fail + full lab report for the exact tube + cap you’re buying.

- Opaque & odor proof pre roll packaging:

- Tube must be opaque in most adult-use states (no visible joint).

- Must be smell proof doob tubes with a proper seal to avoid odor complaints and local nuisance issues.

- Tamper-evident:

- Heat shrink band, tear strip band, or perforated label that clearly shows first opening.

- Label & warning space:

- Enough flat area for THC warnings, universal symbols, ingredient text, batch IDs, and QR codes.

California, New York, and newer medical states tend to be stricter. I always recommend aligning your tubes with the broader child-resistant cannabis packaging rules you’ll see in guides like this 2026 child‑resistant cannabis packaging overview.

Canada (Federal Rules)

For Canada, your pre roll tubes for cannabis need to follow federal packaging rules:

- CR packaging:

- Must meet Canada Consumer Product Safety Act standards (usually ISO 8317 / similar CR proof).

- Supplier should provide test certificates accepted by Canadian regulators.

- Plain packaging style:

- Certain colors, finishes, and branding approaches are restricted.

- You need enough real estate for large health warnings and THC symbol.

- Odor-proof, tamper-evident:

- Tube must stay sealed + smell-proof through transport and long shelf life.

- Tamper evidence is basically mandatory at retail.

Europe (Germany, UK Medical)

For Europe’s current medical markets, compliance is more “pharma-style” than U.S. rec:

- Medical-grade compliance focus:

- Strong preference for ISO 8317 child resistant pre roll tubes.

- Consistent documentation to satisfy GDP/GMP aligned distributors.

- Label space & traceability:

- Need clean flat space for pharmacy labels, batch numbers, and barcodes.

- Often better to choose simple, low-gloss tubes that pass as medical, not recreational.

- Material safety:

- Confirm tubes use EU-compliant plastics (e.g., REACH, food-contact style safety where required) and do not leach into product.

Testing Labs & Documentation to Demand from Suppliers

No matter the market, don’t place a bulk order of wholesale pre roll tubes until you have this paperwork in hand:

- Child-resistance certificates

- Full third‑party lab report (not just a PDF “statement”).

- Report must list your exact tube size, closure type, material, and design.

- Material safety & composition

- Food‑grade or equivalent declaration.

- Heavy metals / contaminant reports if you’re using sustainable pre roll tubes like rPET or PCR.

- Odor & seal performance

- Any internal lab tests for seal integrity, drop tests, and compression.

- If they claim “smell proof doob tubes,” ask how they tested it.

- Country-specific compliance statements

- For U.S. brands: state that packaging meets CPSC 16 CFR 1700.

- For Canada/EU: confirmation of ISO 8317 or equivalent and regulatory alignment.

If a supplier can’t quickly share real CR pre roll tube certification, test data, and material specs, I consider that a red flag and move on.

Cost & MOQ Reality Check for Pre Roll Tubes

When you’re pricing pre roll tubes for cannabis, you need a clear view of unit cost, MOQs, and all the “hidden” extras that hit your margin later.

Wholesale price tiers to expect

Most wholesale pre roll tubes bulk programs price by volume. Rough ballpark (for standard PP child resistant pre roll tubes, unprinted):

- 5,000 units – highest cost per unit (small-batch, good for testing SKUs)

- 10,000 units – noticeable price drop, starter level for most new brands

- 50,000 units – strong cost-per-unit savings, works for growing brands

- 100,000+ units – best pricing, but you need the cash flow and storage

If you’re layering in custom pre roll tubes with logo, the price breaks still follow the same tiers, but the gap between 10k and 50k+ becomes even more important.

Hidden costs nobody tells you about

Sticker shock usually comes from what’s not in the initial quote:

- Tooling & mold changes – any custom diameter, height, or special CR feature can trigger a tooling fee.

- Printing plates or setup – for flexo/screen printing; digital print can avoid plates but may cost more per unit at scale.

- Color matching (Pantone) – exact brand colors often require paid color matching.

- Certification testing – full CR pre roll tube certification (CPSC/ASTM) can add upfront lab costs if you’re developing something custom.

- Freight & duties – especially if you’re importing; this can wipe out “cheap” overseas pricing if you don’t run the math.

If you’re trying to budget your first custom line, this custom pre-roll packaging cost guide from us at Hemployd is a good baseline for real-world numbers: custom pre-roll packaging cost guide.

When custom pre roll tubes are actually worth it

You don’t always need to reinvent the wheel. Here’s how I look at custom vs. off-the-shelf:

Custom tubes make sense when:

- You’re building a long-term core SKU (flagship strain or line).

- You want your pre roll tube packaging to fully replace outer boxes/labels as branding.

- You’re ordering 50k+ units regularly, so branding amortizes nicely.

- You need a unique feature (multi-pack format, special diameter, special CR function).

Off-the-shelf tubes are better when:

- You’re testing new SKUs or seasonal drops.

- You’re unsure of demand and don’t want to sit on dead inventory.

- You’re fine using labels or sleeves for branding instead of direct printing.

- You need product fast and can’t wait for tooling and print lead times.

My advice: start with stock child resistant pre roll tubes plus labels, validate your SKUs and volumes, then lock in custom once you know what actually sells and can justify the MOQs and setup costs.

Top Mistakes Cannabis Brands Make With Pre-Roll Tubes (And How to Avoid Them)

1. Choosing style over certified child-resistance

Too many brands chase “cool-looking” pre roll tubes and forget the most important part: verified child resistance. If the tube isn’t properly certified, you’re exposed to:

- Failed inspections

- Product recalls

- Fines and forced relabeling or repackaging

Always demand proof of CPSC / ASTM / ISO child-resistant certification for any child resistant pre-roll tubes you buy. Ask your supplier for:

- Test reports from accredited labs

- Certificates that match your exact size, closure, and material

- Confirmation that packaging meets your target state or country rules

If a supplier can’t show documentation, walk away. Style is easy to change. Compliance isn’t. If you want a deeper overview of how regulators think, I strongly recommend reading this guide on mastering cannabis packaging regulations: how to stay compliant across different markets.

2. Ignoring odor leakage complaints

If your “smell proof doob tubes” leak odor, you’re not just annoying customers – you’re risking returns, bad reviews, and possibly local complaints.

Common causes:

- Weak or warped seals

- Cheap plastic that flexes under heat

- Lids that don’t fully lock after a few uses

To avoid this:

- Choose odor proof pre-roll packaging with tight, tested seals

- Ask for retention samples and test them in real-world conditions (car heat, pocket, bag)

- Listen to customer service and budtender feedback – if they say it smells, it smells

Odor-proof performance is as important as the logo on the tube. If smell escapes, your brand equity leaks with it.

3. Forgetting about automated filling line compatibility

A lot of brands fall in love with a unique pre roll tube design… then find out it doesn’t run on their automated filling or labeling lines.

Problems you want to avoid:

- Tubes that are slightly off-spec in length or diameter and jam machines

- Unusual shapes that can’t be fed or capped automatically

- Inconsistent wall thickness that throws off weight sensors

Before locking in a tube:

- Get technical drawings and tolerances from your supplier

- Share them with your co-packer or automation vendor

- Run a small test on your line before placing a big wholesale pre roll tubes bulk order

If you plan to scale, “automation-friendly” is non-negotiable for your pre roll tube packaging.

4. Ordering without physical samples

On paper, every pre roll tube looks great. In your hand, it’s a different story.

Ordering tens of thousands of tubes without samples leads to:

- Loose or overly tight caps

- Plastics that feel cheap or brittle

- Colors that don’t match your brand

- Labels that don’t stick well to the surface finish

Always:

- Request physical samples of the exact size, color, and closure

- Test them with your actual pre rolls, labels, and humidity packs

- Drop-test them, smell-test them, and get feedback from your team and budtenders

This simple step saves you from expensive mistakes and delays. If you care about shelf impact and sales lift, it’s also worth understanding how custom cannabis packaging design can boost your brand image and conversion: using packaging as a sales asset, not just a container.

Avoid these four mistakes, and you’re already ahead of most brands when it comes to best pre roll tubes for cannabis that are compliant, practical, and actually loved by customers.

How to Choose the Right Pre-Roll Tube Supplier in 2026

Picking the right partner for your pre roll tubes will make or break your margins, timelines, and compliance. Here’s how I’d evaluate a pre roll tube packaging supplier in 2026.

Red Flags vs Green Flags

| Area | Green Flags (Good Signs) | Red Flags (Walk Away) |

|---|---|---|

| Compliance | Current CR pre-roll tube certification (CPSC/ASTM/ISO) on file, test reports shared | “Child resistant” in marketing, but no lab reports or expired certs |

| Quality | Drop-tested, odor-proof samples, consistent wall thickness, smooth CR function | Lids popping open, leaks, strong plastic smell, inconsistent colors |

| Lead Times | Clear lead times, buffer stock, honest about delays | Vague delivery dates, constant “next week” promises |

| Communication | Dedicated rep, fast replies, transparent quotes | Slow responses, missing details, pressure selling |

| MOQs & Pricing | Clear wholesale pre roll tubes bulk tiers, no hidden fees | Surprise tooling / plate charges after you commit |

| Customization | Real custom pre roll tubes with logo examples, digital proofs, PMS color control | Mockups only, no real samples, can’t match color or finish |

| Sustainability | Options like rPET, PCR, biodegradable sustainable pre-roll tubes with data | “Eco” claims without certificates or material breakdown |

Questions Every Cannabis Brand Should Ask

When I vet a supplier for child resistant pre roll tubes or odor proof pre roll packaging, I always ask:

- What certifications do your CR pre-roll tubes have?

Ask for full reports (CPSC/ASTM/ISO and any state-specific tests). - Can you send physical samples of each size and closure?

Test on your own pre-rolls and automated filling line. - What are your real lead times and inventory levels?

Especially for high-demand sizes like 109mm pre-roll tubes. - What’s included in the price?

Check for hidden costs: tooling, custom colors, plate fees, extra for matte/soft-touch. - Do you support small runs and scale?

Can you start at 5k–10k and scale to 100k+ without changing specs? - What sustainability options do you offer?

PCR %, rPET, biodegradable joint tubes, and proof for claims. - Who else do you supply?

You want experience with real cannabis pre-roll packaging compliance, not generic pharma only.

If you’re going heavy on branding, it helps to work with a partner who understands design, like we cover in our guide to custom pre-roll tubes and branding in 2026.

Why U.S.-Based Inventory + Global Manufacturing Wins

In 2026, the best setup I’ve found is:

- Global manufacturing (Asia/EU/Latin America)

- Lower unit cost on wholesale pre roll tubes bulk

- Access to more materials (PCR, rPET, specialty finishes)

- U.S.-based inventory + logistics

- Faster replenishment to dispensaries and MSOs

- Easier returns, QC checks, and emergency orders

- Less risk from shipping delays, tariff shocks, and customs issues

This hybrid model lets you hit big-brand pricing while still getting reliable stock, better QC, and support in your time zone. For deeper material pros and cons across plastics, glass, and compostables, I also break it down in our comparison of pre-roll tube materials in 2026.

Bonus: Quick-Start Recommendation for New Cannabis Brands

Best all-around pre-roll tube for most brands

If you’re just getting into pre-roll packaging and don’t want to overthink it, here’s what I recommend for 90% of new cannabis brands:

Go with a 109mm child resistant pre-roll tube in PP (polypropylene), 18–19mm diameter, matte finish, odor proof, with custom label or direct print.

Why this setup works almost everywhere:

- Fits most formats: Works for classic 1g king-size pre rolls, infused joints, and slim blunts.

- Fully compliant: Easy to get certified as child resistant pre-roll packaging and meet cannabis pre-roll regulations in strict markets.

- Cost-effective: PP is still the best value material for wholesale pre roll tubes bulk while keeping quality up.

- Odor control: Tight seals = smell proof doob tubes that don’t leak terps in bags or behind the counter.

- Brand flexibility: You can start with labels, then upgrade to custom pre-roll tubes with logo and full-wrap designs as you grow.

If you care deeply about sustainability but still need performance, I’d swap to 109mm rPET CR pre roll tubes as a close second – slightly higher cost, better story for eco-focused markets.

hemployd’s top 3 best-selling pre-roll tubes in 2026

Here’s what’s actually moving the fastest for us and why dispensaries keep reordering.

1. 109mm Matte Black CR Pop-Top Tube (PP) – “The Workhorse”

- Specs: 109mm, 18.5–19mm diameter, child-resistant pop-top, matte black PP

- Why brands love it:

- Looks clean with almost any label or brand color

- Affordable for big wholesale pre-roll tubes bulk orders

- Reliable odor proof pre-roll packaging with solid seal

- Why dispensaries love it:

- Easy to stock, stack, and bag

- Recognizable format for customers – no explanation needed

- Passes the “drop test” and doesn’t crack on shelves

2. 98mm Clear rPET CR Tube with Flat Cap – “The Hybrid”

- Specs: 98mm, 16–18mm diameter, child resistant flat cap, clear rPET

- Best for: Minis, dogwalkers, slim 0.5g pre-rolls

- Why brands love it:

- Sustainable pre-roll tubes with recycled content

- Clear body shows off the actual joint – great for premium flower

- Strong storytelling angle for eco-conscious buyers

- Why dispensaries love it:

- Product is visible without opening

- Customers like seeing grind quality and infusion before buying

3. 109mm Frosted Glass CR Pre-Roll Tube with Custom Cap – “The Premium Move”

- Specs: 109mm frosted glass, CR certified closure, custom-color cap

- Best for: Premium infused joints, rosin-heavy pre-rolls, limited drops

- Why brands love it:

- Instantly feels high-end – huge boost in luxury perception

- Perfect for branded doob tubes for dispensaries that want a top shelf look

- Works great with metallic labels, minimal branding, and QR codes for storytelling

- Why dispensaries love it:

- Easy to position as higher-ticket SKUs

- Customers often keep and reuse the tube – constant brand reminder

If you’re building out a full pre-roll line and want packaging that ties in with your overall brand system, I’d strongly suggest aligning your tube choices with a clear cannabis packaging strategy – this is exactly what we break down in our guide on designing cannabis packaging that builds real brand value in 2026.