Phase 1 – Pre-Production (Weeks 1-2)

Define Your Packaging Type & Budget

First, you’ll need to pick the right packaging style for your hemp product. Here are your top options:

- Rigid boxes: Premium feel, sturdy protection, higher cost.

- Folding cartons: Lightweight and cost-effective, ideal for most cannabis products.

- Mylar + box combo: Great for extra freshness and barrier properties.

Next, understand child-resistant (CR) requirements. The key regulation is 16 CFR 1700.20, covering various CR mechanisms like:

- Push-and-turn caps

- Squeeze-lock features

Choosing the right CR option will impact your design and cost.

Finally, check your minimum order quantity (MOQ). Here’s a quick reality check:

| MOQ | Cost per Unit (Example) | Notes |

|---|---|---|

| 1,000 | Higher unit cost | Good for small launches |

| 10,000 | Lower unit cost | Best for scaling up |

Ramping up MOQ reduces your cost per unit but requires a bigger upfront investment.

Lock in Regulatory Compliance Early

Regulations are complex and vary by state. Lock them in early to avoid costly redesigns:

- Federal agencies: FDA, FTC, CPSC, ASTM D3474 standards.

- State 2025 hotspots: Watch out for CA Prop 65, New York, Colorado, and Florida-specific rules.

- Demand lab-testing certificates from your hemp packaging vendors – no exceptions.

- Download the free hemployd 50-state compliance checklist to cover every legal angle.

Locking in compliance from day one saves headaches and keeps your launch on track.

Ready to nail your packaging foundation? Start with the right type, budget smart, and lock compliance early.

Phase 2 – Design & Material Selection (Weeks 3-5)

Choose Your Hemp Substrate

Picking the right hemp substrate is key to custom hemp packaging that fits your brand and budget. Here’s a quick look at your options:

| Substrate Type | Description | Pros | Cons |

|---|---|---|---|

| 30% Hemp Pulp | Mix of hemp and other fibers | Cost-effective, eco-friendly | Less durable than 100% hemp |

| 100% Hemp Pulp | Pure hemp fibers | Strong, sustainable | Higher cost |

| Hemp-Blend SBS (Solid Bleached Sulfate) | Kraft paper with hemp blended in | Smooth finish, good printing | Less eco-friendly |

Also, consider FSC certification. FSC-certified hemp stock shows you’re using responsibly sourced materials—retailers prefer this and it boosts brand trust.

Thickness matters for durability and feel. Common choices:

- 18pt: Lightweight, good for folding cartons

- 24pt: Stiffer, ideal for premium rigid boxes

- Chipboard + Hemp Wrap: Eco-luxe look, blends natural texture with sturdy feel

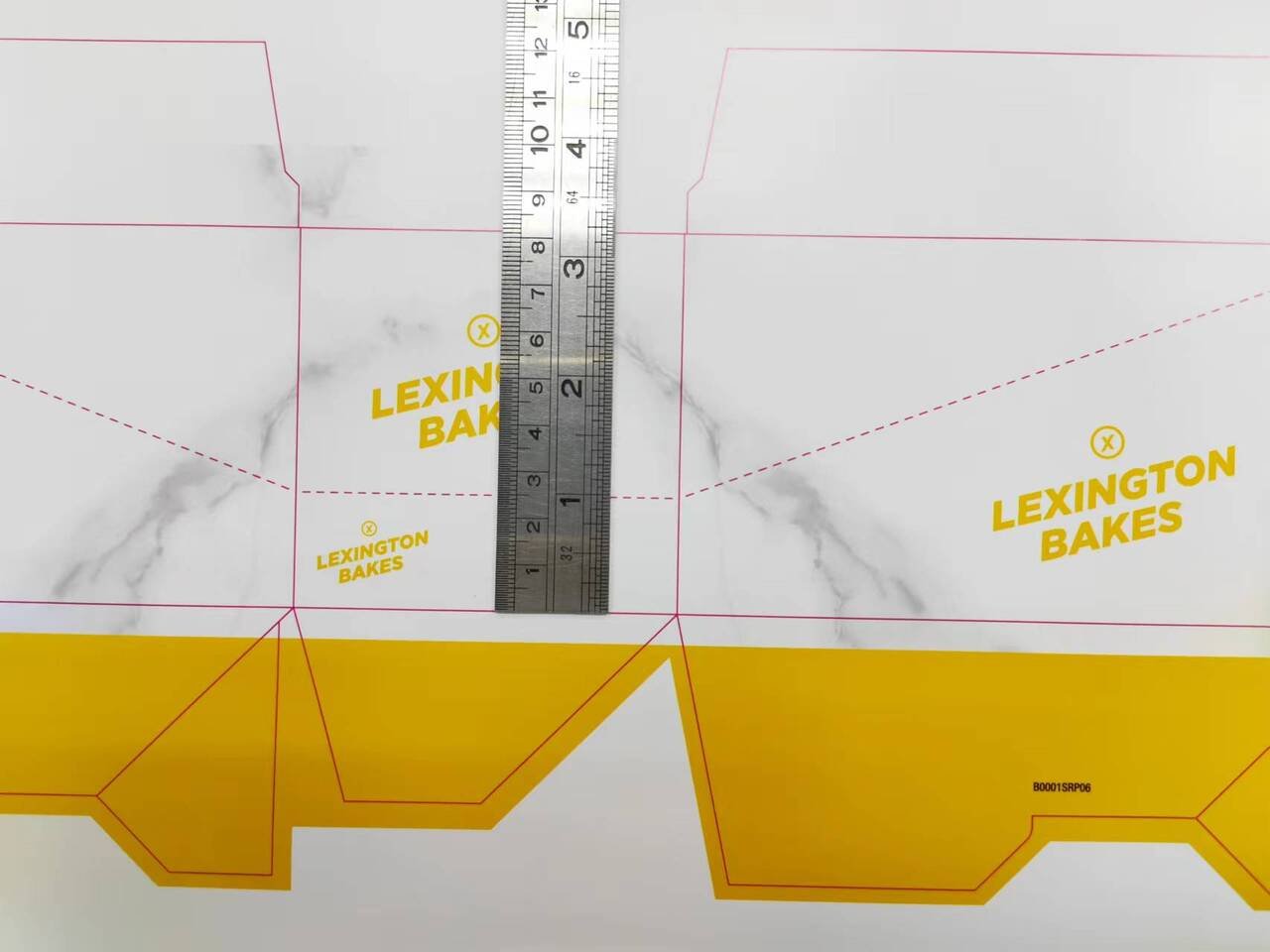

Structural Design (Dielines & 3D Proofs)

Your packaging’s shape and function come to life here. We use trusted software like ArtiosCAD and SolidWorks to create accurate dielines and 3D proofs.

Child-resistant (CR) designs are critical for cannabis packaging compliance. Common CR mechanisms include:

- Push-and-turn caps

- Squeeze-lock slides

- Slide locks with safety tabs

We provide clear diagrams so you understand how these work and fit in your package. Inserts matter too—choose between:

- Thermoformed hemp pulp trays (eco-friendly, molded fit)

- Folded card inserts (simple, cost-effective)

Graphic Design & Branding

Stay fresh with 2025 cannabis design trends:

- Minimalist layouts

- Pharmaceutical, clean looks

- Luxury, high-end finishes

Label must-haves:

- THC warnings and dosage info

- QR codes for product traceability

- Net weight and ingredients

Printing eco-friendly? Use soy-based inks and aqueous coatings, which avoid harsh chemicals. Finishes like soft-touch matte give a premium feel while staying sustainable.

This phase balances sustainability, style, and strict hemp packaging regulations to get your product shelf-ready in the U.S. market.

Phase 3 – Pre-Press & Sampling (Weeks 6-8)

Proofing Rounds That Actually Matter

At this stage in the custom hemp packaging process, getting your proofs right saves time and money down the line. Here’s the usual flow:

- Digital Proof: Quick, cost-effective, and perfect for catching early design hiccups.

- Plated Proof: More detailed, showing how colors will separate for printing; expect a slightly higher cost and about a week turnaround.

- Physical White Sample: A blank package prototype made from the actual hemp substrate—great to check structure and feel.

- Printed Mock-Up: Your final preview, complete with full graphics on hemp stock, so you can inspect print quality, colors, and finishes before full run.

Each round typically takes 3-7 days depending on complexity. Budget accordingly—digital proofs run under $100, plated up to a few hundred, physical samples $300+, and printed mock-ups around $500.

Child-Resistant Certification Process

If you’re making child-resistant hemp packaging, certification is a must. We work with top US third-party labs like Intertek, SGS, and Lab42 to handle testing under 16 CFR 1700.20. The protocol is strict:

- Test Groups: 50 adults and 100 kids must try opening your packaging within 10 minutes.

- Pass Rate: Adults should open it easily, kids should fail consistently.

Hemployd’s in-house CR labs help brands nail this on the first try with a 98.7% first-pass success rate, cutting delays and extra costs. We guide you through prepping your design and samples to meet these tough standards upfront—no guesswork needed.

This rigorous pre-press and certification step ensures your sustainable cannabis packaging not only looks great but passes legal and safety checks before production kicks off.

Phase 4 – Manufacturing & Quality Control (Weeks 9-12)

Printing & Converting on Hemp Packaging

When it comes to hemp packaging manufacturing, choosing the right printing method is key. Offset printing works great for larger runs with consistent color, while digital printing offers flexibility for smaller batches or variable data. Hemp fiber handles both well but needs careful setup. You can enhance your packaging with inline foil stamping, embossing, or spot UV to add that premium, eco-friendly touch. Just remember, die-cutting hemp stock requires tighter tolerances because it’s more fibrous than regular paperboard.

Folding, Gluing & Child-Resistant Assembly

For assembling child-resistant (CR) hemp packaging, hot-melt glue is preferred for stronger bonds on CR tabs compared to cold glue. Automation plays a big role here—once you hit minimum order quantities (usually 5,000+ units), robotic assembly lines speed up folding and gluing while maintaining quality.

Quality Control Checkpoints

Before your hemp boxes ship, expect a rigorous 12-point inspection covering:

- Seam strength to ensure durable construction

- Color accuracy evaluated by Delta-E measurements

- Child-resistant torque tests to meet safety regulations

- And a Certificate of Analysis (C.O.A.) confirming inks are free from heavy metals

This thorough quality control guarantees your packaging is safe, sturdy, and compliant—essential for sustainable cannabis packaging production in the U.S. market.

Phase 5 – Logistics & Launch (Weeks 13-14)

Packaging Validation & Drop Testing

Before your hemp packaging hits the shelves or ships out, it needs to pass real-world tests. We follow the ISTA 3A protocol, which is the gold standard for e-commerce shipments. This ensures your packaging can handle drops, bumps, and rough handling during transit—no cracked jars or crushed boxes.

For sensitive products like gummies and pre-rolls, we run temperature and humidity cycling tests. These checks guarantee your hemp packaging maintains its protective qualities against moisture and heat changes, keeping your product fresh and intact.

Final Delivery & Reorder Strategy

Understanding lead times in 2025 is key to smooth launches. Here’s how the landscape looks for hemp packaging manufacturing:

- China: Longer lead times, often 6-8 weeks, with potential delays.

- USA: Faster turnaround, usually 3-4 weeks, great for quick launches and tight deadlines.

- Mexico: Balanced option—4-6 weeks and reliable shipping routes.

For brands preparing for the busy crop season, inventory buffering is a must. Stock up ahead to avoid last-minute shortages and missed sales.

At hemployd, we also offer a 72-hour rush reorder program, perfect if you need more hemp boxes fast without compromising quality. This program gives US brands the flexibility to stay ahead in a competitive market.

With these logistics and launch strategies, your custom hemp packaging moves seamlessly from factory to storefront, ready to impress cannabis customers nationwide.

2025 Cost Breakdown Table for Hemp Packaging

When planning your custom hemp packaging, understanding the cost difference between ordering 1,000 units versus 10,000 units can save you big. Here’s a quick look at what you’re likely to pay, plus some hidden fees to watch out for:

| Quantity | Estimated Cost per Unit | Total Cost Estimate |

|---|---|---|

| 1,000 Units | $3.50 – $4.20 | $3,500 – $4,200 |

| 10,000 Units | $1.85 – $2.30 | $18,500 – $23,000 |

Key Notes:

- Costs include: materials (hemp pulp or blend), printing, child-resistant features, and assembly.

- Bulk orders reduce per-unit costs but require larger upfront investment.

- Hidden fees to avoid:

- Plate charges for printing setup

- Child-resistant lab testing fees

- Rush order tariffs when accelerating manufacturing

For sustainable cannabis packaging, budget carefully to get the right balance between quality and price. Knowing these costs upfront lets you approach hemp packaging vendors with confidence and ensures your project fits local US market demands without surprises.

Common Mistakes That Delay Launches 60+ Days

Launching hemp packaging can hit major snags if you miss key details. Here are 7 red flags we see all too often that cause delays of two months or more:

-

Wrong substrate choice

Using non-FSC-certified or incompatible hemp blends can throw off printing and durability tests.

-

Missing <0.3% THC declaration

This legal disclaimer is mandatory on packaging. Skipping it causes compliance rejections.

-

Ignoring child-resistant (CR) standards

Overlooking specific 16 CFR 1700.20 requirements leads to costly redesigns and recertifications.

-

Inaccurate labeling space

Not leaving enough room for THC warnings, QR codes, and required info slows down approvals.

-

Unclear dielines and proofs

Submitting incomplete or incorrect dielines confuses manufacturers and stalls production.

-

Lack of proper lab test certificates from vendors

Without valid heavy metal or fiber content certifications, your packaging won’t pass quality control.

-

Hidden cost surprises

Forgetting to budget for plate charges, CR lab fees, or rush tariffs can halt production midstream.

Avoid these common pitfalls to keep your hemp packaging project on track and launch on time.

Why Brands Choose hemployd in 2025

Brands pick hemployd because we get hemp packaging done faster and smarter. Here’s how we stand out in the US market:

| Benefit | What It Means for You |

|---|---|

| 47-day average turnaround | Almost half the industry standard (89 days). Faster launch times mean quicker sales. |

| In-house Child-Resistant (CR) lab | No waiting on third parties. We handle testing on-site, cutting delays and ensuring compliance. |

| 100% hemp-blend stock library | Access a full range of hemp substrates without extra minimum order fees. More choices, less hassle. |

| Free compliance audit + dieline starter pack | We help you avoid costly regulatory mistakes from day one—no extra charge. |

With hemployd, you get reliable, eco-friendly hemp packaging made specifically for US cannabis brands aiming to stay ahead in 2025’s regulated landscape.