Child-resistant packaging needs to stop 80% of children under five from getting to the contents for at least 10 minutes. This fact jumped out at me while researching child resistant packaging manufacturers in Canada. These safety standards are just the start of a complete set of requirements.

Canada’s packaging world has changed a lot since 1977, especially when you have cannabis becoming legal. The industry now covers pharmaceuticals, household cleaners, and cannabis products. Most manufacturers employ 11-50 specialists to meet current market needs.

You just need to find reliable manufacturers who meet Health Canada’s strict rules and deliver quality packaging. That’s why I took time to assess and put together this list of 10 top child-resistant packaging companies in Canada. These companies have shown what they can do through certification standards, smart designs, and solid compliance track records.

Let me show you the best options I found so you can make a smart choice for your packaging needs.

How to Research child resistant packaging manufacturers

![]()\

Image Source: Canada.ca

Finding reliable child-resistant packaging manufacturers needs careful research and evaluation. My experience working with suppliers of all sizes has helped me develop a practical approach to identify trustworthy manufacturers.

The first step involves verifying certification compliance. I ask potential suppliers to show proof of certification that confirms they follow required regulations [1]. This documentation will give a clear picture that the manufacturer produces genuine child-resistant packaging instead of making claims they can’t validate.

The track record of suppliers needs to be broken down by asking about marketplace failures [1]. These questions gave an explanation about product quality and supplier reliability. My research shows that 90% of children must be unable to open a properly tested package to qualify as child-resistant [2].

Testing facilities approved by the Consumer Product Safety Commission (CPSC) are a great way to get a detailed evaluation. These facilities give a full picture following protocols outlined in 16 CFR § 1700.20 [3]. The testing process lets real children try to open packages containing safe placebo substances [2].

The sort of thing I love about effective child-resistant packaging is how it needs film and converting partners to work together [4]. The whole package must be child-resistant, not just the closure or opening mechanism.

My checklist while researching manufacturers includes:

-

Pre-evaluations that give honest feedback before testing

-

Mini studies that assess package performance

-

Market research capabilities for consumer priorities [2]

The CPSC managed to keep lists of special package manufacturers, testing facilities, and consultants [2]. International distribution requires compliance with ISO standards, recognized by organizations like:

-

American National Standards Institute (ANSI)

-

Standards Australia (SA)

-

Association Française de Normalization (AFNOR) [5]

Manufacturers must understand senior-friendly requirements. Testing panels include adults aged 50-70 years without physical or mental disabilities [5]. This dual testing approach makes packages both child-resistant and available for adults.

The CPSC can be reached at SBO@cpsc.gov [2] for updated information about package manufacturers and testing facilities.

Hemployd: Your Trusted Partner for Custom Cannabis Packaging

My research into child-resistant packaging manufacturers shows Hemployd as a standout company. They focus on cannabis packaging solutions. Their quality work and compliance have made them a respected name in Canada’s packaging industry.

Hemployd’s Manufacturing Capabilities

Hemployd creates custom cannabis packaging through advanced manufacturing systems. Their production lines can make 30 to 300 cannabis pouches every minute [6]. The company’s facilities use food-grade mylar bags made for pre-rolls, flowers, and edibles [7]. They have an impressive range of child-resistant mechanisms. These include push-and-turn designs that need multiple coordinated movements [6].

Hemployd’s Industry Compliance & Legal Knowledge

The company follows Poison Prevention Packaging Act standards strictly [8]. Testing panels check each package with children aged 42-51 months and adults aged 50-70 years [8]. Their packages have all needed warning labels about adult-use only, pregnancy risks, and storage instructions [8].

Hemployd’s Quality Assurance & Standards

Hemployd runs thorough testing protocols for quality control. They test child-resistant features according to 16 CFR 1700.15(b) specifications [8]. The materials they use meet food-grade requirements, which is crucial for edibles and concentrates [9].

Hemployd’s Logistics & Fast Delivery Solutions

The company’s delivery system works really well. They provide DDP (Delivered Duty Paid) service and handle taxes and customs clearance [7]. Large orders of millions take 5-20 days to produce [7]. Customers get regular updates with pictures and videos during production [8].

Hemployd’s Minimum Order & Client Focus

Hemployd doesn’t require minimum orders but offers better prices for larger quantities [7]. They help clients with free artwork design services. Sample options range from white samples to pre-production printed versions [7]. The company’s reasonable pricing and great after-sales support show their commitment to long-term partnerships [7].

Cannasupplies: Pioneer in Cannabis-Specific CR Packaging

![]()\

Image Source: cannasupplies.ca

Cannasupplies, a division of PharmaSystems Inc., has been the life-blood of Canada’s cannabis packaging industry for 25 years [10]. The company pioneers cannabis packaging breakthroughs and delivers reliable solutions that meet strict safety standards.

Cannasupplies Manufacturing Capabilities

The company draws its manufacturing strength from its worldwide sourcing network and contract manufacturing abilities [11]. Their Toronto warehouse acts as a distribution hub that serves all of Canada quickly [2]. The company introduced a groundbreaking 50% Post-Consumer Recycled Polypropylene material for their patented child-resistant container line through collaboration with Amcor Rigid Packaging [5].

Cannasupplies Certification Standards

Cannasupplies holds both Class I and Class II Health Canada Medical Establishment Licenses [10]. Their steadfast dedication to quality goes beyond simple requirements, as shown by their ISO certification status [10]. Each product goes through rigorous testing to meet Poison Prevention Act standards [12].

Cannasupplies Product Range

Their product lineup includes:

-

Packaging solutions for dried cannabis and extracts

-

Containers for edible cannabis products

-

Specialized packaging for cannabis topicals [10]

The company’s trailblazing designs feature sliding lid tins with child-resistant locks that fit easily in pockets without sacrificing product security [13]. They create custom solutions in different colors that give brands room to stand out [13].

Cannasupplies Pricing Structure

Cannasupplies offers competitive pricing that helps boost their customers’ net income [2]. They give flexible ordering choices for both case and pallet quantities [2]. The company delivers value through efficient end-to-end approaches and deep market expertise [11].

The company started its journey in 2014 and leads the way in meeting the changing needs of Canada’s cannabis industry [14]. Their knowledge of regulations and detailed product range makes them a trusted partner for businesses that need compliant packaging solutions [14]. Their partnership with Berlin Packaging helps them grow across North America and provides improved capabilities to serve the expanding cannabis market [14].

Cannabis Secure: Innovation in Child-Resistant Design

![]()\

Image Source: The National Cannabis Industry Association

Safety drives Cannabis Secure’s mission to develop groundbreaking child-resistant packaging solutions. Their packaging meets strict standards – 85% of children cannot open these packages within 5 minutes [1].

Cannabis Secure’s Proprietary Technologies

The company’s breakthrough comes from their patented locking mechanisms. Their designs use push-down-and-turn and squeeze lock technologies that need two separate motions to open [15]. Each mechanism goes through thorough testing under ASTM D3475-18 standards [16]. A notable advance is their tamper-evident rings for bottles and child-resistant zippers made for flexible pouches [16].

Cannabis Secure’s Industry Compliance

Cannabis Secure follows federal regulations strictly in US and Canadian markets [1]. Their testing matches 16 CFR Part 1700.20 specifications, so packages resist access by children aged 42-51 months [16]. The company goes beyond simple requirements – their packaging earns certification from the Consumer Product Safety Commission (CPSC) [3].

Cannabis Secure’s Custom Solutions

Cannabis Secure creates tailored solutions for cannabis products based on market needs. Their product line has:

-

Push-and-turn caps made for THC beverages that fit standard 202-260 aluminum can formats [4]

-

High-barrier pouches with secure closures in different sizes [17]

-

Recyclable HDPE #2 plastic options that help environmental sustainability [4]

The company puts safety and functionality first in their designs. Their packaging solutions show clear warning labels and THC level indicators [3]. Adults can still open these packages easily, striking the right balance between child resistance and ease of use [15].

Cannabis Secure thinks over state-specific rules and adds features like opaque materials for edibles and tamper-evident seals [18]. Their designs stay away from bright colors or appealing graphics that might catch children’s attention [3]. They focus on professional, compliant packaging that serves both safety and practical purposes.

Cannabis Secure keeps improving their designs through work with testing facilities. They test package performance with pre-evaluations and mini studies [16]. This all-encompassing approach helps their solutions meet both regulatory requirements and market needs effectively.

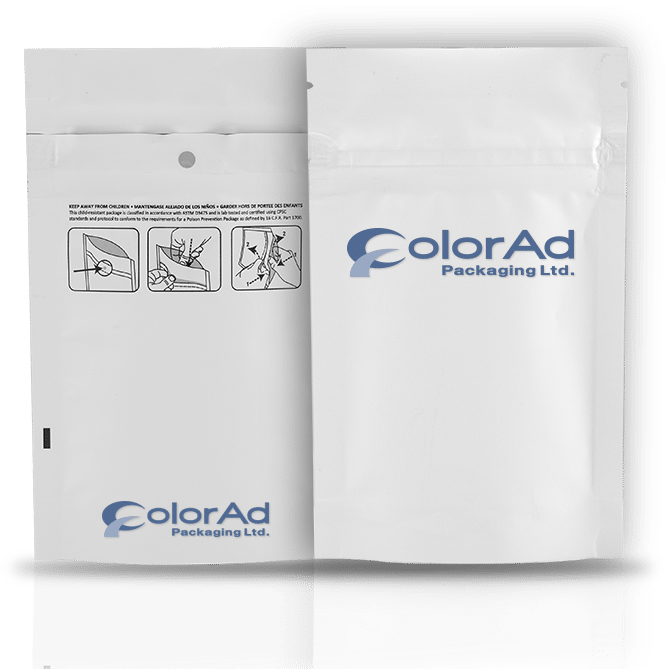

Color Ad Packaging: Leading Lab-Certified Solutions

![]()\

Image Source: Color Ad Packaging Ltd.

Color Ad Packaging combines North American quality with innovation. I’ve seen their steadfast dedication to lab-certified child-resistant solutions firsthand. The company operates from two modern manufacturing facilities and has set industry standards in flexible packaging since 2000 [7].

Color Ad’s Testing Protocols

Color Ad’s SecureSack went through extensive third-party laboratory evaluation using Consumer Product Safety Commission protocols [19]. Children between 42-51 months tried to access the contents for 10 minutes during testing. The results were remarkable – 80% of children failed to breach the packaging throughout the testing period [20]. Senior adults aged 50-70 then tested these packages, and 90% opened and reclosed them successfully within specified timeframes [20].

Color Ad’s Material Innovation

Color Ad takes a unique approach to materials. Their facilities create multi-layer laminated roll stock and preformed stand-up bags [7]. The company excels at both cold-seal and heat-seal coating applications [7]. They maintain precise color management through automated systems as North America’s first G7 certified gravure packaging printer [21].

Color Ad’s Market Specialization

The company specializes in industries that need child-resistant packaging. A startling statistic reveals that laundry pods injure one child every hour [22]. This led Color Ad to develop specialized pouches for:

-

Harmful chemicals and medications

-

Cannabis and marijuana products

-

Ammunition storage solutions

-

Even sugar-containing products that need extra safety measures [22]

Their SecureSack maintains child-resistant properties with openings from 3.62" to 12" [22]. Each package follows Title 16, Section 1700.15 of the Code of Federal Regulations for poison prevention standards strictly [19]. The company demonstrates quality control through tightly controlled manufacturing processes [23].

Color Ad stands out with their steadfast dedication to green packaging solutions [7]. They combine safety features with environmental consciousness, making them the top choice for premium brands seeking ethical packaging solutions [7]. Their worldwide customers benefit from centralized manufacturing locations that ensure efficient distribution and consistent quality standards [7].

Dymapak: Specialized Safety Solutions

Image Source: Dymapak

My research into Dymapak shows their state-of-the-art approach to child-resistant packaging. Their patented Secure Sack design has proven excellent results in independent safety trials [8].

Dymapak’s Safety Features

Dymapak’s flagship Secure Sack uses a patented press-to-close zipper design that keeps various products safe, from vape cartridges to cannabis concentrates [8]. Their latest creation, the Squeeze & Turn Tin, uses metal-on-metal construction without any plastic parts and protects against light, oxygen, and moisture exceptionally well [24]. Users can hear and feel when the package closes securely [25].

Dymapak’s Industry Applications

Testing shows that Dymapak’s solutions work well across many sectors. Their child-resistant pouches serve as primary packaging in smaller sizes while larger formats work as secondary packaging [26]. Companies can customize their packages with up to nine-color printing in glossy and matte finishes [8]. The prices stay competitive – their 1000-count packages cost between $204 and $397 [27].

Dymapak’s Quality Standards

Laboratory testing validates every product before release [28]. The Secure Sack has earned four utility patents and several lab certifications as child-resistant that meet CPSC 16 CFR 1700 standards [28]. The company’s 40+ years of manufacturing expertise ensures strict quality control [28]. They go beyond simple safety measures – all materials meet food-grade standards needed for pharmaceutical and consumer packaged goods [26].

Dymapak’s Customer Support

Dymapak provides detailed support throughout the packaging development process. Resources help customers tailor pouches to their exact needs [26]. A dedicated support line lets customers get direct consultation when needed [29]. The team focuses on creating memorable, safe, and secure packaging solutions [28].

The company demonstrates its commitment to state-of-the-art solutions through eco-friendly initiatives. Their Squeeze & Turn Tin marks a major step forward in recyclable packaging [25]. This solution tackles both environmental concerns and safety requirements and could replace billions of plastic child-resistant closures thrown away each year [30].

PKGMAKER: Custom CR Packaging Excellence

Image Source: pkgmaker.com

My evaluation of packaging manufacturers led me to find PKGMAKER’s unique approach to child-resistant packaging solutions. The company’s 40 years of experience in flexible packaging [31] makes them a leader in providing green practices and compliant solutions.

PKGMAKER’s Design Process

The company designs space-saving, economical solutions that protect product integrity. Their packages provide excellent leak resistance and odor control with premium materials [31]. PKGMAKER’s innovative online platform streamlines the design process and provides professional branding support from start to finish [6].

PKGMAKER’s Manufacturing Standards

PKGMAKER runs strict quality control measures in their modern production facility. They complete orders within 72 hours of approval [6]. Their flexible packaging options demonstrate several advantages:

-

Direct printing removes the need for separate labels

-

High-barrier materials will give a superior product protection

-

Child-resistant zippers provide better safety [31]

PKGMAKER’s Client Services

PKGMAKER shows steadfast dedication to customer service excellence. Their skilled design team works closely with clients, whatever the order size [6]. The company provides detailed support throughout package development:

They help select the right packaging methods based on product needs. The team then determines the best size specifications. Their focus shifts to creating designs that grab consumer attention in stores [31].

The company’s support goes beyond the sale. Quick shipping gets products to customers fast, and friendly service representatives stay available for ongoing help [6]. This integrated approach has helped them build strategic collaborations with global businesses and new entrepreneurs [6].

PKGMAKER sets itself apart with flexible ordering. They accept orders of all sizes without sacrificing quality or attention to detail, unlike competitors who require large minimum quantities [6]. Their expertise shines especially when handling pharmaceutical products that just need sterile, high-barrier packaging with exact specifications [31].

AMW Consumer Packaging: Comprehensive Solutions

![]()\

Image Source: amwconsumerpackaging.com

My research to find dependable child-resistant packaging manufacturers led me to AMW Consumer Packaging, a global leader with 30+ years of expertise [32]. The company stands out by combining state-of-the-art solutions with practical applications in the packaging industry.

AMW’s Product Portfolio

AMW creates custom solutions using a variety of materials. Their child-resistant packaging includes ASTM-approved CR technology for bottles, jars, tubes, and tins [9]. The company’s commitment to plastic-free alternatives stands out – their CR packaging achieves 100% recyclability while maintaining safety standards [9].

AMW’s Industry Experience

AMW has built a reliable network since 1984 by working with manufacturers worldwide [9]. The company’s expertise extends to consumer products, food and beverage, and beauty and cosmetics sectors [33]. They deliver high-quality packaging solutions customized to each product’s specific needs [34].

AMW’s Quality Assurance

Strict quality control measures guide AMW’s production process. Each packaging solution undergoes complete testing to meet child-resistant standards that protect against accidental access [34]. AMW also adopts eco-friendly practices in their operations while maintaining product effectiveness [35].

AMW’s Market Reach

AMW serves both consumer and industrial sectors as a global packaging distributor [32]. Their service model combines design, production, and delivery smoothly [32]. A nationwide warehousing and distribution network helps reduce packaging costs and speeds up market access [35].

AMW’s dedication to creating unique experiences for each brand sets them apart [35]. They develop packaging solutions that protect products effectively and improve brand identity through creative design elements [35].

ND Supplies: Innovative Safety Designs

![]()\

Image Source: ND Supplies

ND Supplies has become a leader in developing environmentally responsible child-resistant packaging solutions among other industry pioneers. The company combines state-of-the-art technology with strict safety standards, which has made it a trusted name in Canada’s packaging sector.

ND Supplies’ Technology Integration

The company’s manufacturing facilities follow strict quality control measures to meet rigorous safety standards [36]. Their proprietary database has evolved over 16 years and contains evidence-based information from more than 15,000 contractors [37]. ND Supplies’ in-house software solutions provide immediate tracking and customization options that make the production process more efficient [37].

ND Supplies’ Compliance Standards

ND Supplies, an ISO 9001 certified company [36], shows steadfast dedication to quality management. Their child-resistant packaging goes through extensive field testing to meet Health Canada’s Cannabis Act requirements [11]. The company goes beyond simple safety requirements – each product line must pass multiple quality control checkpoints [36].

ND Supplies’ Customer Success Stories

ND Supplies succeeds because of its client-focused approach. The core team creates solutions that preserve product potency while ensuring child safety [11]. Notable achievements include:

-

Developing reusable, durable packaging that promotes brand awareness

-

Creating secure shipping solutions that maintain product integrity

-

Using environmentally responsible methods that reduce single-use plastics [11]

The company’s expertise covers cannabis products of all types, from edibles to concentrates. Their child-resistant solutions prevent children from accessing cannabis-infused products like gummies and chocolates effectively [11]. ND Supplies uses customer feedback to optimize their product selection based on market trends [36].

The company stands out because of its dedication to environmentally responsible packaging without compromising safety features. Their reusable designs help reduce environmental impact [11]. Advanced technology in manufacturing ensures consistent product performance across their packaging solutions [36].

Green Rush Packaging: Versatile CR Solutions

![]()\

Image Source: greenrushpackaging.com

My analysis of Green Rush Packaging revealed their wide range of child-resistant solutions that help multiple industries. Their state-of-the-art approach combines safety with functionality and sets new standards in protective packaging.

Green Rush’s Product Range

The company makes specialized child-resistant packaging in a variety of categories. Their GRIP ‘N PULL™ series has exit bags from quarter-ounce to large sizes, with prices between $204.99 to $541.49 per case [38]. They’ve developed the Grip ‘N Turn™ glass containers for concentrate packaging, which come in 5ml to 9ml capacities [13].

Green Rush’s Manufacturing Process

Green Rush maintains strict quality control measures in their modern facilities. They can produce custom glass jars, bottles, and barrier bags [39]. The company’s Pyro™ Pre Roll Case shows their innovative spirit. This crush-proof design holds up to five pre-rolled cones safely, each 109mm long [40].

Green Rush’s Industry Focus

The cannabis sector benefits most from Green Rush’s solutions across product categories. Their child-resistant packaging line has:

-

Pop-top bottles for flower and edible packaging

-

Glass and polystyrene options for concentrate containers

-

Glass tubes and cases for pre-roll packaging

-

GRIP ‘N PULL™ technology for vape packaging [41]

Green Rush stands out with their eco-friendly approach. They use post-consumer recycled materials to help protect the environment [40]. The company goes beyond standard offerings and provides complete design services to customize bags, glass jars, bottles, and exit packaging [39].

Safety remains Green Rush’s top priority through strict child-resistant standards. Each package goes through rigorous testing to keep children under five out while remaining easy for adults to open [42]. The company meets all opacity requirements, which keeps products hidden until opened [42].

Tricanna Industries: Specialized Processing Solutions

![]()\

Image Source: StratCann

Tricanna Industries, a licensed Cannabis Processor in Mission BC, creates innovative solutions for child-resistant packaging needs. My evaluation of their facilities shows how they blend advanced technology with practical processing solutions.

Tricanna’s Technical Capabilities

The company makes precise joints with semi-automated pre-roll manufacturing in customizable cone papers and sizes [43]. Their radio frequency pasteurization process makes them unique by reducing yeast and mold naturally present in cannabis products [44]. They know how to preserve terpenes and moisture content throughout treatment, which keeps product quality high [44].

Tricanna’s Service Options

Premium packaging solutions are Tricanna’s strength. Their selection includes glass jars, PET containers, and mylar bags [43]. My analysis revealed an integrated Quality Management System that makes quality assurance smooth [5]. This system tracks inbound and outbound production items and shows immediate stock quantities [5].

Tricanna’s Market Position

Tricanna holds strong connections with provincial distribution boards as a Health Canada Standard Licensed Processor [43]. They put about two million dollars into facility improvements and equipment [44]. Their choice to focus only on processing, without creating their own brand, gives them a unique market position [44].

Cultivators, brands, and processors benefit from Tricanna’s affordable solutions. Their facility sits one hour outside Vancouver and serves as a central hub for cannabis processing [44]. A strategic collaboration with Ziel Cannabis makes them BC’s only toll processor using the Apex machine [44].

Tricanna stands out because of their support for craft cannabis producers. Their processing license helps cultivators avoid maintaining expensive packaging facilities, so they can focus on growing premium products [44]. The company’s Bills of Materials and Routes system creates optimal workflow and ensures accurate production planning and forecasting [5].

LiquiMedLock: Pharmaceutical-Grade Protection

![]()\

Image Source: www.liquimedlock.com

LiquiMedLock, an 11-year old company, has become a trusted name in pharmaceutical packaging. The company specializes in child-resistant and tamper-evident solutions [12].

LiquiMedLock’s Safety Standards

The company demonstrates its commitment to safety through independent testing and certification. Each product goes through thorough evaluation to meet ASTM D3475 Poison Control Prevention Standard of Packaging for Child Resistance [12]. Their child-resistant, leakproof caps stop children and pets from accessing medications and keep them secure [12]. The tamper-evident feature helps track chain of custody and reduces medication diversion risks [12].

LiquiMedLock’s Industry Applications

My evaluation shows LiquiMedLock’s expertise spans multiple sectors. The company focuses on supporting opioid agonist therapy programs with specialized packaging solutions [12]. Their product line covers:

-

Methadone bottles with unique two-in-one child-resistant, tamper-evident caps [10]

-

Secure methadone lock boxes with mini padlocks [10]

-

Child-resistant pop-top vials and bottles [10]

-

Specialized urine collection devices [10]

LiquiMedLock’s Innovation Focus

Smart packaging technologies drive the company’s innovative approach. Their research explores adding advanced features that could track:

-

Exact time and day of cap removal

-

Frequency of package access

-

Changes in bottle weight

-

Dosage compliance data [45]

Safety and efficiency shape their product design philosophy. Their table-top methadone bottle capper makes batch filling simple [12]. The combined child-resistant and tamper-evident features in a single cap remove the need for separate seals, which streamlines the fill process [45]. Their leakproof caps enable precise medication dosing and support patient recovery programs by preventing medication loss [12].

Comparison Table

| Manufacturer | Certification/Compliance | Manufacturing Capabilities | Product Specialization | Key Features/Breakthroughs |

|---|---|---|---|---|

| Hemployd | PPPA standards compliance, 16 CFR 1700.15(b) testing | Produces 30-300 cannabis pouches per minute | Cannabis packaging, pre-rolls, flowers, edibles | Push-and-turn designs, food-grade mylar bags |

| Cannasupplies | Class I and II Health Canada Medical Licenses, ISO certified | Global sourcing network with Toronto warehouse hub | Cannabis packaging, dried cannabis, extracts, topicals | Sliding lid tins with CR locks, custom color options |

| Cannabis Secure | CPSC certification, ASTM D3475-18 standards | Not mentioned | THC beverages, cannabis pouches | Push-down-and-turn mechanisms, tamper-evident rings |

| Color Ad | G7 certified gravure packaging printer | Multi-layer laminated roll stock and preformed bags | Chemicals, medications, cannabis, ammunition | SecureSack technology with automated color management |

| Dymapak | CPSC 16 CFR 1700 standards | 40+ years of manufacturing expertise | Vape cartridges, cannabis concentrates | Secure Sack design with Squeeze & Turn Tin |

| PKGMAKER | Not mentioned | Delivers within 72 hours | Pharmaceutical packaging | Direct printing technology and child-resistant zippers |

| AMW | ASTM-approved CR technology | Global manufacturing network | Consumer products, food and beverage, cosmetics | 100% recyclable CR packaging |

| ND Supplies | ISO 9001 certified | Multiple quality checkpoints | Cannabis edibles, concentrates | Reusable packaging designs |

| Green Rush | Child-resistant standards compliance | Custom glass and barrier bag production | Cannabis flower, edibles, concentrates, vapes | GRIP ‘N PULL™ technology |

| Tricanna | Health Canada Standard Licensed Processor | Semi-automated pre-roll production | Cannabis processing, packaging | Radio frequency pasteurization |

| LiquiMedLock | ASTM D3475 compliance | Not mentioned | Pharmaceutical packaging, opioid therapy | Two-in-one CR tamper-evident caps |

Conclusion

These 11 Canadian manufacturers stand at the forefront of child-resistant packaging with their steadfast dedication to safety, breakthroughs, and quality. Each company brings something special to the table – from Hemployd’s specialized cannabis solutions to LiquiMedLock’s pharmaceutical-grade protection.

Safety standards top the priority list for manufacturers of all sizes. Their products must stop 80% of children under five from getting inside while remaining available to adults. These companies put substantial resources into testing and certification that meets Health Canada’s strict regulations.

Sustainability drives these manufacturers forward. Cannasupplies now creates recycled polypropylene materials while Dymapak designs plastic-free alternatives. These breakthroughs help businesses achieve both safety requirements and environmental targets effectively.

The packaging industry adapts quickly to market changes. Green Rush and ND Supplies create specialized solutions for emerging markets like cannabis. Color Ad and AMW, both decades old, have expanded their product lines to serve multiple sectors.

Your specific needs should guide the choice of packaging manufacturer. The right fit depends on minimum order quantities, customization options, and industry expertise. The comparison table above matches your requirements with the ideal manufacturer quickly.

Reaching out to several manufacturers about your project details is a great way to get the perfect match. You’ll find the best partner that meets all safety and regulatory requirements for your child-resistant packaging needs.

References

[1] – Crativ Packaging

[2] – Cannasupplies Cost Competitive Solutions for Pre-Rolls

[3] – Ibex Packaging Child Resistant Packaging

[4] – Food Engineering Magazine – Child Resistant Can Lock for Cannabis Beverages

[5] – Evo Technologies Case Study – Tricanna Industries

[6] – Hemployd

[7] – Hemployd

[8] – Hemployd

[9] – Hemployd

[10] – LiquiMedLock

[11] – ND Supplies Child Resistant Packaging

[12] – LiquiMedLock About

[13] – Green Rush Packaging – Grip ‘N Turn Child-Resistant Containers

[14] – Berlin Packaging – Cannasupplies Acquisition

[15] – Marijuana Packaging Solutions – Child Resistant Packaging

[16] – RXDCO Child Resistant Packaging

[17] – Kind Pack USA

[18] – Gamut Packaging Guide to California Cannabis Packaging Rules

[19] – Color Ad Packaging CFR-1700.15

[20] – Drug Plastics Child Resistant Packaging Testing

[21] – Color Ad How We Make It

[22] – Color Ad What We Make

[23] – Color Ad

[24] – Dymapak Child-Resistant Tins

[25] – Dymapak Sustainable Child-Resistant Packaging

[26] – Dymapak Child-Resistant Bags

[27] – Dymapak Shop

[28] – Dymapak Press Release – New Industry Standard Packaging

[29] – Dymapak Contact Us

[30] – Dymapak Curbside Recyclable Tin

[31] – PKGMAKER

[32] – AMW Consumer Packaging Products & Services

[33] – AMW Consumer Packaging

[34] – AMW Consumer Packaging Child-Resistant Packaging

[35] – AMW Consumer Packaging Blog

[36] – ND Supplies

[37] – C-R Solutions Testimonials

[38] – Green Rush Packaging Grip ‘N Pull Bags

[39] – Green Rush Packaging

[40] – Growcycle Pre-roll Packaging

[41] – Green Rush Packaging Child Resistant Packaging

[42] – Packaging Digest – Marijuana Packaging

[43] – Tricanna

[44] – Stratcann – Tricanna Industries

[45] – LiquiMedLock Harm Reduction Packaging